Wastewater treatment plants (WWTPs) are essential infrastructures as they play a crucial role in completing the urban water cycle. By ensuring proper treatment and water reuse, they are key to protecting water resources while also directly influencing air qualityAir quality refers to the state of the air we breathe and its composition in terms of pollutants present in the atmosphere. It is considered good when poll...

Read more.

During the treatment and biological digestion processes that take place within these facilities, gases such as hydrogen sulphide (H2S), ammonia (NH3), methane (CH4), nitrous oxide (N2O) and volatile organic compounds (VOCs) are often released. These are responsible for strong and unpleasant odours and for gaseous emissions which, once in the air, can become potentially harmful.

Wastewater treatment plants emit nearly twice as many greenhouse gasesGreenhouse gases (GHGs) are natural and anthropogenic gases that trap heat in the Earth's atmosphere, regulating the planet’s temperature. However, when ...

Read more, such as methane and nitrous oxide, as previously estimated, placing them among the major sources of air pollution and climate change. This finding reinforces the urgency of implementing advanced emission control and monitoring technologies to mitigate these impacts on both local and global air quality. El Abbadi, S.H. et al. (2025).

The following sections examine how WWTPs affect air quality by releasing gases and odours, and how implementing advanced environmental monitoring solutions, such as those developed by Kunak, helps identify emission sources, quantify and reduce pollutants in real time.

This approach allows the development of strategies to optimise control and operational efficiency measures that ensure healthier and more sustainable environments in which to coexist with these facilities.

Proper wastewater management is essential to protect public health and the environment.

Why can wastewater treatment plants affect air quality?

Besides protecting aquatic ecosystems, WWTPs are also potential sources of atmospheric pollutants. This occurs during the wastewater purification process, where physical, chemical and biological treatments are applied in the stages of pretreatment, sedimentation, aeration, anaerobic digestion and sludge dewatering. These processes remove suspended solids, organic matter, nutrients and microorganisms while generating various gaseous compounds that can affect local air quality.

Air Quality Innovation in Just 1 Click

Stay informed about the air you breathe!

Subscribe to our newsletter to receive the latest updates on environmental monitoring technology, air quality studies, and more.

The main emissions come from biological reactors with aeration systems, where the volatilisation of ammonia (NH3)Invisible yet powerful: ammonia (NH3) is a colourless gas which, although naturally present in the atmosphere in small amounts, can become an unwelcome ene...

Read more and volatile organic compounds (VOCs) can be particularly significant. In anaerobic digesters, microbial activity produces biogas with high concentrations of methane (CH4)Methane, known chemically as CH4, is a gas that is harmful to the atmosphere and to living beings because it has a high heat-trapping capacity. For this ...

Read more and carbon dioxide (CO2)Carbon dioxide (CO2) is a gas that occurs naturally in the atmosphere and plays a crucial role in the life processes of the planet. This gas, also known as...

Read more, along with traces of hydrogen sulphide (H2S).

These gases have a significant environmental and health impact, contributing to the spread of odorous gases such as H2S and NH3, which not only degrade environmental quality but can also cause corrosion problems in metallic infrastructures.

Furthermore, the mechanical dewatering and forced ventilation areas of WWTPs may release VOCs derived from the degradation of detergents, fats and industrial products present in wastewater.

Taken together, these emissions, in addition to their direct environmental impact and the greenhouse effect of CH4 and CO2, represent a major challenge for air quality management around treatment plants. Without proper control measures such as gas capture systems, biofiltration, tank sealing, controlled ventilation and continuous odour and gas monitoring, they can cause odour nuisance, occupational risks and non-compliance with emission regulations.

Main gases and odours generated in WWTPs

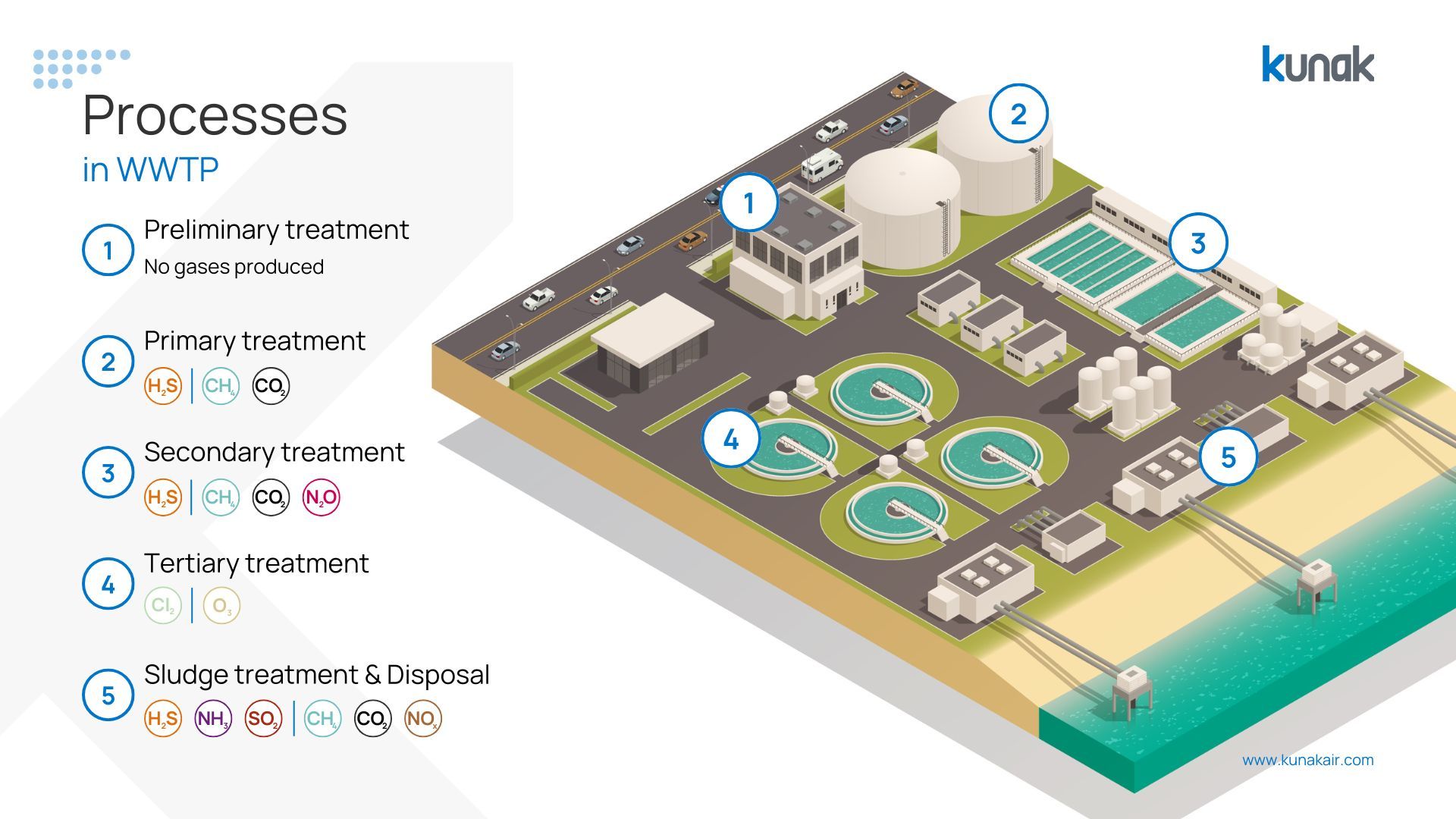

Processes and gases generated in a WWTP

Wastewater treatment in a WWTP consists of several stages, each involving specific processes where different pollutant gases are produced:

| Treatment stage in the WWTP | Generated gases | Health effects and associated nuisances |

|---|---|---|

Preliminary treatmentRemoval of coarse waste and large materials before the main treatment. |

No significant gases are generated. | No direct health impact; the main risk comes from exposure to aerosols or physical particles. |

Primary treatmentSedimentation of solids and separation of particulate organic matter. |

|

|

Secondary treatmentBiological processes using microorganisms to degrade organic matter. |

|

|

Tertiary treatmentRemoval of specific contaminants and final disinfection. |

|

|

Sludge treatment and disposalManagement and stabilisation of solid waste generated in previous stages. |

|

|

Each stage in a WWTP is designed to perform specific functions in wastewater treatment and is associated with different gaseous emissions, many of which contribute to air pollution issues caused by gases and odours such as the following:

H2S and NH3: gases responsible for odour nuisance

Hydrogen sulphide (H2S) is one of the most characteristic and problematic gases produced in wastewater treatment plants. It originates mainly from the anaerobic decomposition of organic matter containing sulphur compounds, especially in areas with poor oxygenation or where sludge and organic residues accumulate. Due to its high volatility, H2S is easily released into the atmosphere in parts of the facility such as anaerobic digesters, sludge storage and transport systems, and tank ventilation points.

This gas is notable for its very pungent odour at low concentrations, similar to that of rotten eggs, which causes considerable olfactory discomfort in surrounding areas. However, at higher concentrations, H2S becomes a health hazard, as it can cause irritation of the eyes and respiratory tract, headaches and, in prolonged exposure or at elevated concentrations, neurotoxic effects and severe systemic damage.

In Poland, it was found that 41.6% of Environmental Protection Inspectorate intervention requests between 2016 and 2021 were related to odour nuisance. […] Detailed identification of the substances causing odour problems in wastewater treatment plants revealed that hydrogen sulphide (H2S), ammonia (NH3) and volatile organic compounds (VOCs) were the most common odorous substances in these facilities. Joanna Czarnota, J., Masłoń, A. and Pajura, R. (2023).

Mercaptans (CH4S), also known as thiols, are sulphur-based organic compounds with very strong and unpleasant odours, commonly found in emissions from wastewater treatment plants along with H2S. They are responsible for smells similar to rotten cabbage or garlic and are among the main contributors to odour problems in these facilities, together with hydrogen sulphide and other sulphur compounds. They have a very low odour threshold, meaning they can be detected by the human nose at minimal concentrations. Effective management of mercaptans in WWTPs through proper monitoring and treatment is essential, as they can cause corrosion and toxicity issues in addition to generating offensive odours and neighbour complaints.

Ammonia (NH3) in WWTPs mainly derives from the biological degradation of nitrogenous compounds in wastewater and sludge. Its high solubility in water allows it to coexist in both liquid and gaseous phases within the plant, with emissions particularly occurring during aeration, storage and sludge dewatering processes. Ammonia is a colourless but irritating gas that affects the eyes and respiratory tract and contributes to the formation of secondary particles (PM2.5), which worsen air pollution and have adverse respiratory effects. Moreover, its emissions are harmful to nearby vegetation, affecting agriculture and local biodiversity through soil eutrophication and acidification.

Various studies have shown that inhaling ammonia causes inflammation of respiratory tissue and can trigger bronchospasms and irreversible lung damage, highlighting the importance of controlling its emissions in industrial environments to protect public health. US Agency for Toxic Substances and Disease Registry (ATSDR).

Emissions from wastewater treatment plants, in addition to their direct environmental impact and the greenhouse effect of CH4 and CO2, represent a major challenge for managing air quality around such facilities.

From the regulatory perspective, both gases are covered by the Directive 2008/50/EC, which sets air quality objectives for the protection of human health and the environment in the European Union. It includes limits for SO2 (as a precursor of H2S) and NH3 concerning their toxic effects and their role in the formation of suspended particles.

In Spain, Royal Decree 102/2011 complements these European guidelines by establishing limit values for air pollutantsAir pollution caused by atmospheric contaminants is one of the most critical and complex environmental problems we face today, both because of its global r...

Read more, measurement standards and specific control programmes to reduce emissions in industrial and urban areas, including WWTPs.

In occupational health and industrial safety (EHS), exposure to H2S is particularly critical. Concentrations above 10 parts per million (ppm) are considered hazardous and pose an immediate risk to workers. Therefore, regulations require the implementation of ventilation systems to ensure proper air renewal in emission areas, as well as detection and early warning devices through continuous monitoring to prevent intoxication and accidents. It is also recommended that personnel receive specific training on response protocols in case of concentration peaks and on the safe handling of equipment.

In short, the strict control of H2S and NH3 emissions in wastewater treatment plants is essential not only to minimise nuisance and environmental impact but also as a direct commitment to the health and safety of nearby communities and workers.

One of the main concerns surrounding these facilities is the neighbour complaints caused by unpleasant and persistent odours that can affect the quality of life in nearby residential areas. Although these emissions may sometimes be perceived as minor nuisances, they can cause social tension, damage the public perception of environmental management and trigger conflicts between operators and local communities. For this reason, implementing continuous monitoring systems, adopting effective mitigation technologies and establishing transparent communication channels with residents are key actions to address this issue proactively and sustainably.

When it comes to odour mitigation, the ability to monitor emissions and target odour sources has become essential for developing effective odour management strategies that enable facilities to maintain critical community relations.

Environmental monitoring of WWTPs helps optimise operational control and efficiency measures to ensure healthier and more sustainable environments.

Volatile organic compounds (VOCs)

These are a broad group of substances characterised by their high volatility at ambient temperature, which allows them to easily shift to the gaseous phase. In the context of WWTPs, these compounds are mainly generated through the biological decomposition of organic matter, sludge fermentation and the use of various chemical products during cleaning and maintenance operations. Among the most common VOCs found in these facilities are aldehydes, ketones, alcohols and volatile fatty acids. They are identifiable by their sweet, rancid or unpleasant odours, which considerably increase odour nuisance.

Beyond their olfactory impact, many VOCs play a significant role in atmospheric chemistry, as they actively participate in photochemical reactions that promote the formation of tropospheric ozone (O3), a major secondary pollutant that affects air quality in urban environments and can cause respiratory health issues. Therefore, managing and mitigating VOC emissions in WWTPs is essential to control odours and reduce the broader environmental impacts associated with air pollution and public health.

Control strategies usually involve capture technologies, biofiltration and optimisation of biological processes to reduce the generation and release of these gases. Likewise, current environmental legislation at both European and national levels establishes the obligation to monitor and limit VOC emissions, recognising their importance as pollutants and precursors of complex environmental problems.

Greenhouse gases in wastewater treatment plants

The greenhouse gases (GHGs) emitted by wastewater treatment plants are one of the most relevant aspects to consider due to their contribution to climate change.

These emissions mainly consist of methane (CH4) and carbon dioxide (CO2), generated during anaerobic digestion and biological oxidation of the organic matter contained in wastewater. Although part of the biogas produced during anaerobic digestion is recovered and used for on-site energy production, a considerable fraction may be inadvertently released into the atmosphere if gas capture and storage systems are not properly managed.

These emissions are directly linked to climate neutrality and circular economy goals, which require a sustained and controlled reduction of the environmental footprint generated by WWTPs. European environmental policy promotes the technological optimisation and modernisation of these infrastructures to minimise greenhouse gas emissions. Therefore, measures such as continuous monitoring, advanced control of biological processes and energy recovery from organic waste through anaerobic digestion and biogas production are being implemented.

In addition to methane and carbon dioxide, WWTPs also emit nitrous oxide (N2O), a GHG with a global warming potential approximately 300 times higher than CO2, produced mainly in aerobic and anoxic stages of biological wastewater treatment. For this reason, research projects and emerging technologies are focusing on optimising aeration and operational conditions to reduce its production.

Consequently, reducing the climate impact of WWTPs requires an integrated approach combining technological innovation, operational efficiency and the transition towards more sustainable energy models that promote environmentally responsible development.

Gas capture systems, biofiltration, tank sealing, controlled ventilation and continuous monitoring of odours and gases minimise odour nuisance, occupational risks and compliance issues related to diffuse emissions.

Gas monitoring in wastewater treatment plants

Today, the technological breakthrough of monitoring atmospheric pollutants with real-time sensors has revolutionised the ability to detect gases emitted by wastewater treatment plants, as it allows the identification of concentration peaks in real time, something not achievable with traditional spot-sampling methods. This preventive capability is crucial to anticipate and mitigate operational or health problems associated with gas emissions.

Why measure and monitor emissions

Gas monitoring in WWTPs is essential for proper environmental, operational and safety management. Continuous monitoring ensures compliance with current regulations by keeping gaseous emissions within legal limits and prevents community conflicts arising from persistent odours.

Moreover, the collected data enable the optimisation of internal processes such as aeration, covering systems or chemical treatment adjustments, improving the efficiency of the purification process.

From an occupational safety perspective, early and continuous detection of toxic gases is vital to protect workers, enabling the identification of dangerous concentrations that may pose immediate risks. The traceability provided by continuous sensor-based monitoring systems is also key to maintaining verifiable records that ensure transparency and facilitate proper tracking of environmental conditions.

In summary, integrating continuous and high-precision monitoring systems represents a strategic investment for WWTPs, contributing to environmental sustainability, regulatory compliance and the protection of public and occupational health.

Odour management in wastewater treatment plants includes preventive actions to avoid the formation of odorous compounds, impact minimisation and end-of-process odour purification systems. When prevention or minimisation actions are insufficient to mitigate these emissions, odour treatment technologies must be applied. Activated carbon is often used because it can easily adsorb a wide range of odorous compounds such as volatile organic compounds (VOCs), ammonia, mercaptans and hydrogen sulphide. Lebrero et al., 2011; Márquez et al., 2021a, 2021b.

Sewer systems are the network of pipes that collect and transport wastewater and rainwater.

Available technologies

The technologies available for gas monitoring in wastewater treatment plants have evolved significantly in recent years. Traditionally, odour and gas measurement was performed using methods such as dynamic olfactometry, passive tubes or manual sampling followed by laboratory analysis, which, while accurate, only allow periodic campaigns and do not provide continuous tracking.

Today, intelligent and continuous monitoring using multiparameter sensors represents a major advance, delivering real-time data integrated into digital platforms for analysis, alert generation and modelling. These systems combine electrochemical technologies, optical sensors and NDIR (non-dispersive infrared) techniques, offering high temporal resolution and minimal operator intervention.

Gas analysers are indispensable tools for modern wastewater management. They not only protect personnel and the environment but also improve plant performance. Choosing the right system supports regulatory compliance, enhances safety and increases long-term profitability.

For instance, gas analysers based on NDIR and similar technologies are ideal for detecting methane (CH4) and carbon dioxide (CO2) in anaerobic digesters, while electrochemical sensors complement the detection of toxic gases such as hydrogen sulphide (H2S) and ammonia (NH3). Some advanced equipment uses tunable diode laser absorption spectroscopy (TDLAS) to measure ammonia with high precision. At Kunak, this technique is also used to detect methane, even in high-humidity environments common in WWTPs. Additionally, there are portable technologies such as FTIR and UV-DOAS analysers for multifrequency and multicomponent field measurements.

These technologies are designed for the harsh environments typical of treatment plants, offering resistance to corrosion, humidity and suspended particles, and are compatible with industrial control and SCADA systems (a comprehensive digital solution for supervising, controlling and systematising industrial processes and infrastructures in real time). This facilitates real-time data integration and management, allowing operational optimisation, ensuring regulatory compliance, preventing occupational hazards and improving environmental management.

Early warning and source location system for H2S emissions in a wastewater treatment plant – Kunak

Kunak solutions for wastewater treatment plants (WWTPs)

Kunak solutions for wastewater treatment plants are the Kunak AIR Pro and AIR Lite stations. Specifically designed for advanced environmental monitoring in industrial and urban environments, their modular architecture allows the installation of interchangeable cartridges to monitor key gases such as CO, NO, NO2, O3, SO2, CO2, H2S, CH4, VOCs, NMHC, NH3, HCl, HCN, HF and O2, offering one of the widest ranges of real-time air pollutants available on the market. These stations also enable the monitoring of particulate matter such as PM1, PM2.5, PM4, PM10, TSP and TPC.

The stations integrate with digital data management platforms and atmospheric dispersion models via the Kunak API, facilitating the rapid detection of odour peaks and episodes, the correlation with meteorological data such as wind direction and speed, and the automatic sending of alerts to plant staff to enable immediate response. They also support regulatory compliance and emission traceability, both of which are essential for environmental management and regulatory control.

Thanks to IoT connectivity and calibration in accordance with the CEN/TS 17660 European standard and the US Environmental Protection Agency’s EPA/600/R protocols, metrics and target values for air sensors, Kunak equipment provides accurate, comparable and reliable measurements. This ensures more precise, efficient and trustworthy environmental management, making it a highly valued solution in the wastewater treatment sector.

By combining technological robustness, accuracy, versatility and digital integration capacity, Kunak solutions stand out as essential tools for effective environmental monitoring in the most demanding wastewater treatment plants.

Pollutant gases from wastewater treatment plants have a major environmental and health impact and contribute to the spread of unpleasant odours.

Odour and emission control strategies

Identification of emission sources

Odour and emission control in wastewater treatment plants starts with the precise identification of the most critical emission sources. These include:

- Sludge lines and anaerobic digesters.

- Aeration tanks and secondary clarifiers.

- Sludge storage and transport systems.

- Ventilation ducts and partial covers.

The use of concentration maps generated by distributed sensors across the plant makes it possible to locate these sources, correlate them with meteorological conditions such as wind direction and speed, and prioritise effective corrective actions.

Mitigation and optimisation

Once sources are identified, several proven techniques are applied to mitigate emissions:

- Selective covering of tanks and emission areas to reduce the direct release of gases.

- Biofilters and percolating biofilters, which remove odorous gases through biological degradation by microorganisms.

- Chemical treatments such as the dosing of oxidants (hydrogen peroxide, sodium hypochlorite, potassium permanganate) to neutralise odorous compounds.

- Controlled ventilation systems that optimise air flow and reduce internal gas concentrations, improving safety and environmental conditions.

The integration of Kunak sensors in these processes, by providing real-time data, allows for the automatic adjustment of these operations, optimising energy consumption and increasing the efficiency of odour treatment. Thanks to an approach based on continuous monitoring and dynamic response, it is possible to ensure regulatory compliance, minimise nuisance to nearby communities, promote social acceptance and reduce environmental impacts, thus enabling sustainable and efficient plant management.

The most effective chemical treatments for odour removal

In the field of wastewater treatment, controlling odorous compounds is essential to maintain environmental quality and the wellbeing of nearby communities. The most effective chemical methods for reducing and eliminating odours are mainly based on oxidation processes and adsorption and neutralisation techniques, which transform or capture the molecules responsible for odours.

Oxidising compounds

Oxidising agents react directly with odorous gases such as hydrogen sulphide (H2S), mercaptans (CH4S) and ammonia (NH3), converting them into odourless or low-odour compounds.

The most commonly used compounds include:

| Oxidising compound | Chemical formula | Mechanism of action | Advantages and considerations |

|---|---|---|---|

| Hydrogen peroxide | H2O2 | Oxidises H2S, converting it into elemental sulphur or sulphates, thus reducing odours. | Effective in pumping stations and treatment plants. Acts quickly and produces no hazardous residues, although dosage control is required. |

| Chlorine dioxide | ClO2 | Oxidises odorous compounds such as H2S, NH3 and mercaptans without producing chlorinated organic by-products. | Highly efficient and stable. A safer, more environmentally friendly option, but requires careful handling. |

| Potassium permanganate | KMnO4 | Reacts with H2S and other odorous gases, oxidising and eliminating their smell. | Used in air filtration or pretreatment systems. Very effective but can leave solid residues (MnO2). |

| Chlorine and sodium hypochlorite | Cl2 / NaClO | Act as disinfectants and oxidants, reducing odorous gases such as H2S and NH3. | Commonly used in water treatment. Effective but must be controlled to prevent formation of chlorinated by-products. |

| Ozone | O3 | Immediately oxidises odorous molecules, neutralising volatile organic compounds and sulphurous gases. | Very powerful oxidant with rapid action. Requires specific generation equipment and safety systems to prevent direct exposure. |

Adsorption and neutralisation techniques

These techniques physically remove or reduce odorous molecules through their retention or chemical neutralisation.

- Activated carbon: a porous material with a large internal surface area capable of adsorbing gases and volatile organic compounds (VOCs). Commonly used in air filtration systems located at ventilation points or tank covers.

- Neutralising and masking products:

- Neutralisers: formulations that react with odorous gases (H2S, NH3 and mercaptans) to eliminate their odour potential.

- Masking agents: fragrances that temporarily conceal odours without removing them. Their use is limited, as they can create more intense mixed odours if applied excessively.

The choice between oxidation and adsorption depends on the nature of the compounds, the process stage where they are generated and the associated operating costs. Many facilities combine both methods, such as chemical oxidation followed by activated carbon filtration, to achieve a more complete elimination.

Key aspects to consider

Selecting the right treatment requires an understanding of the chemical composition of the gases and the concentration of odorous compounds present in each phase of the process. It is also necessary to assess safety, cost and efficiency criteria before implementation.

In practice, the most effective systems combine oxidation and adsorption processes, adjusting chemical dosages according to meteorological conditions and the airflow being treated.

Kunak’s environmental monitoring systems are key allies in this task. Through multiparameter sensors, Kunak AIR stations can detect in real time peaks in H2S, NH3 and VOC concentrations, enabling early alerts and optimising chemical dosing. These stations include individually calibrated sensors following rigorous procedures that ensure traceability, accuracy and reliability of information in real-world environments.

As a result, wastewater treatment plants can reduce odorous emissions, support regulatory compliance and minimise their environmental impact. Moreover, the remote management and flexibility of these Kunak systems facilitate their integration into safety and maintenance protocols, optimising both resources and operational performance.

Kunak monitoring panel with tools for source identification and emission quantification in a wastewater treatment plant – Kunak

Benefits of advanced environmental monitoring

Implementing an advanced environmental monitoring network in a wastewater treatment plant provides multiple technical, operational and social benefits that positively impact overall plant management. Firstly, it supports regulatory compliance and traceability by continuously generating verifiable data for inspections or environmental audits, helping demonstrate effective emission control.

From an operational perspective, the early detection of abnormal emissions allows:

- Regulatory compliance and traceability: continuous data provide verifiable evidence for environmental inspections or audits, ensuring compliance.

- Predictive maintenance: reduces costs and intervention times before losses, structural damage or public complaints occur.

- Improved public perception: a key benefit, as reducing unpleasant odours and ensuring transparency strengthen relations with local communities, fostering trust and acceptance of wastewater infrastructure.

- Support for strategic decision-making: data integration with atmospheric dispersion models and predictive analysis facilitates investment planning and prioritisation of operational improvements.

- Contribution to sustainability and smart cities: when connected to urban environmental data platforms, WWTPs become active nodes in municipal climate and energy management systems.

Ultimately, these measures applied to wastewater treatment plants help them become aligned with global sustainability and efficiency goals and position them as essential elements within more sustainable and resilient urban systems.

Wastewater from toilets reaches treatment plants, where proper treatment allows it to be safely returned to the environment without contaminating rivers and aquifers.

Frequently asked questions about emissions and odours in WWTPs

Which gases should be measured in a WWTP to control odours?

In a wastewater treatment plant (WWTP), odour control is essential to minimise the impact on the environment and the quality of life of nearby communities. To achieve this, it is necessary to measure gases such as hydrogen sulphide (H2S), mercaptans (CH4S), ammonia (NH3) and volatile organic compounds (VOCs), as they are the main contributors to odour nuisance. These compounds are generated during biological treatment processes and in sludge accumulation areas, and can cause discomfort even at very low concentrations.

In addition to odour control, it is also necessary to evaluate the plant’s overall environmental impact by monitoring other gases such as methane (CH4), carbon dioxide (CO2) and sulphur dioxide (SO2)Sulphur dioxide (SO2) is a colourless gas with a pungent odour that causes an irritating sensation similar to shortness of breath. Its origin is anthropoge...

Read more. CH4 and CO2 are greenhouse gases that contribute to climate change, while SO2 can cause acid rain and affect human health. Measuring these gases enables mitigation strategies to be implemented and enhances the plant’s sustainability.

The integration of continuous monitoring systems for these gases enables more efficient WWTP management by anticipating critical situations and optimising treatment processes. It also facilitates compliance with environmental regulations and promotes a more responsible and environmentally conscious operation.

How does hydrogen sulphide (H2S) affect air quality?

Hydrogen sulphide (H2S) is a highly volatile gas characterised by its distinctive rotten egg smell, noticeable even at very low concentrations. It is mainly produced during the decomposition of organic matter in anaerobic environments such as wastewater treatment plants, landfills or chemical industries. Its presence in the air can cause odour nuisance, degrade environmental quality and generate complaints from nearby residents.

At high concentrations, its effects go beyond unpleasant odours. It can cause eye, throat and respiratory irritation and pose a health risk to workers with prolonged exposure. This gas also has corrosive properties that damage metal structures, pipes and equipment, accelerating wear and increasing maintenance costs in industrial facilities.

For these reasons, controlling hydrogen sulphide is essential in any environment where it may occur. Implementing proper detection and ventilation systems, together with safety protocols, reduces associated risks and ensures safe working conditions. Monitoring H2S also helps maintain good air quality and comply with current environmental regulations.

What technology is used for real-time gas measurement in treatment plants?

In wastewater treatment plants (WWTPs), real-time gas measurement is essential to ensure effective emission and odour control. Advanced technologies based on electrochemical and optical sensors are used, capable of detecting very low concentrations of gases such as H2S, NH3 or VOCs with high precision and stability. These technologies enable continuous monitoring, facilitating rapid decision-making whenever gas levels deviate from permitted limits.

Electrochemical sensors are particularly useful for detecting toxic gases such as hydrogen sulphide or carbon monoxide, while optical sensors, such as those based on infrared spectroscopy, excel at detecting gases such as methane and carbon dioxide. Combining different sensor types within one system allows for comprehensive air quality monitoringControlling air quality is an essential task in order to enjoy optimal environmental conditions for healthy human development and to keep the environment i...

Read more across facilities.

A notable example of this technology is Kunak’s AIR Pro and Air Lite stations, which integrate multiple sensors into a single compact device. These stations allow the automatic transmission of real-time data to digital platforms, enabling remote analysis and the configuration of alerts. They also feature remote calibration systems, reducing the need for on-site maintenance and improving operational efficiency in WWTPs.

Is there specific regulation on odours and emissions in WWTPs?

There is no European directive exclusively regulating odours in wastewater treatment plants (WWTPs), but a broader regulatory framework exists that addresses pollutant emissions in general. At EU level, the Directive 2008/50/EC on ambient air quality and the Directive 2010/75/EU on industrial emissions establish limits and obligations to minimise the environmental impact of such facilities.

In Spain, Royal Decree 102/2011 regulates the improvement of air quality, including parameters related to odours such as volatile organic compounds and ammonia. This decree sets out criteria for the assessment and management of atmospheric pollution, also applicable to WWTPs when their emissions affect the surrounding environment.

Furthermore, many autonomous communities have developed specific regulations on odour immissions and occupational exposure limits tailored to their territorial conditions. These complement national and European frameworks, allowing for more precise odour management to protect both workers and nearby populations.

The integration of international standards and studies on odour measurement, assessment and regulation is generally based on global references. For instance, in developing Chile’s first odour standard, key references included:

- Bokowa et al. (2021): a summary and overview of global odour regulations, covering international experiences and regulatory approaches.

- Invernizzi et al. (2020): assessment of odour impact based on short-term environmental concentrations, using models and comparisons from multiple sites.

- Díaz et al. (2019): analysis of existing regulations on odour pollution and impact criteria, within European citizen science projects such as D-NOSES (H2020).

What advantages does continuous monitoring offer over spot sampling?

Continuous gas monitoring in wastewater treatment plants offers a significant advantage over spot sampling as it enables the detection of concentration peaks, unexpected events and their real-time alerts. This ability is crucial to respond immediately to critical situations such as intense odour emissions or leaks of hazardous compounds, minimising environmental impact and enhancing operational safety.

By recording data continuously, it is also possible to analyse trends over time, helping identify recurring patterns and optimise processes. This information is essential for implementing preventive measures, adjusting operational parameters and anticipating potential incidents before they escalate into major problems.

Equally important, continuous WWTP monitoring generates a valuable data history for pollutant dispersion studies, infrastructure improvement planning and environmental audits. These records demonstrate effective emission control to regulatory authorities and support strategic decision-making based on solid technical evidence.

Wastewater treatment plants must develop strategies to optimise control and operational efficiency measures to ensure healthier and more sustainable environments.

Measure to transform: how to achieve a sustainable WWTP

Wastewater treatment plants (WWTPs) are essential for the sustainability of the water cycle, but their operation involves the generation of gases and odours that, if not properly controlled, can deteriorate air quality and affect both nearby communities and plant workers. In the face of this challenge, continuous environmental monitoring using advanced sensors and connected technologies, such as Kunak’s solutions, stands out as an indispensable tool for the effective reduction of emissions.

Measuring accurately and in real time is the first step to prevent nuisance, ensure safe working environments and comply with the most demanding regulatory standards. The ability to analyse, correlate and respond to environmental data enables WWTPs to optimise their processes and minimise their environmental footprint. In a global context defined by the ecological transition and decarbonisation commitments, plants that integrate these intelligent technologies become active nodes within smart cities, contributing to the efficient management of air and energy at the urban level.

Kunak stands out in this field by providing modular monitoring solutions calibrated to European standards, which ensure traceability, prevention and continuous improvement of air quality in wastewater treatment facilities. Thus, digitalisation and technological innovation become strategic allies to turn the environmental challenges of WWTPs into opportunities for progress towards a cleaner and healthier future.

Scientific and technical references

- El Abbadi, S.H., Feng, J., Hodson, A.R. et al. (2025). Benchmarking greenhouse gas emissions from US wastewater treatment for targeted reduction. Nat Water 3, 1133–1143. https://doi.org/10.1038/s44221-025-00485-w

- Constantin, C. et al. (2025). Dispersion modeling of odour emissions from area sources in a municipal wastewater treatment plant. Atmosphere 2025, 16(5), 577; Special Issue Environmental Odour (2nd Edition). https://www.mdpi.com/2073-4433/16/5/577

- Czarnota, J., Masłoń, A., & Pajura, R. (2023). Wastewater treatment plants as a source of malodorous substances hazardous to health, including a case study from Poland. International Journal of Environmental Research and Public Health, 20(7), 5379. https://doi.org/10.3390/ijerph20075379

- Viteri, G., Aranda, A., Díaz-de-Mera, Y., Rodríguez, A., Rodriguez-Fariñas, N., & Rodríguez, D. (2025). Assessment of airborne pollutants in wastewater treatment plants. Environmental Science and Pollution Research International, 32(21), 12868–12882. https://doi.org/10.1007/s11356-025-36484-3

- Toledo, M., & Muñoz, R. (2025). Odour prevention strategies in wastewater treatment and composting plants: a review. Journal of Environmental Management, 375, 124402. https://doi.org/10.1016/j.jenvman.2025.124402

- Márquez, P., Muñoz-Serrano, E., Gutiérrez, M.C., Siles, J.A., Martín, M.A. (2024). Odour impact simulation of a large urban wastewater treatment plant through the numerical solution of a Eulerian model. Journal of Environmental Management, 372, 123327. https://doi.org/10.1016/j.jenvman.2024.123327

- Caimanque, D. (2021). Lessons learned in developing the first odour standard in Chile. 9th IWA Conference on Odours and VOC/Air Emissions, Bilbao, Spain, Olores.org. https://olores.org/index.php?option=com_content&view=article&id=1149:aprendizajes-en-la-elaboracion-de-la-primera-norma-de-olores-en-chile&catid=28:odour-regulations&lang=es&idU=1&acm=_319