The environmental impact of the cement industry is particularly evident in the release of particulate matter (PM10, PM4, PM2.5, and PM1), along with emissions of other pollutants such as nitrogen oxides (NOx) and sulfur dioxide (SO2). Additionally, the carbon footprintIn a world increasingly affected by climate change, understanding how our everyday actions contribute to its worsening has become essential. The carbon foo...

Read more of cement is significant, given that production requires high energy consumption which currently relies predominantly on fossil fuels.

Cement production accounts for approximately 7% of global CO2 emissions, highlighting the urgent need for solutions to reduce its environmental impact and promote more sustainable development. The emissions generated negatively affect both the environment and human health, making rigorous and continuous monitoring essential.

A notable example is the air quality monitoring project developed by Kunak at the CEMEX plant in Monterrey, Mexico, which has demonstrated the effectiveness of advanced technology in improving environmental management in cement plants.

Cement is fundamental to the global economy, as it, along with concrete — its main derivative — supports major infrastructure and urban constructions. However, this industrial activity causes environmental impacts from raw material extraction to manufacturing processes, mainly affecting the atmosphere. Therefore, technological solutions for cement emissions control are essential.

Analysis of the environmental impact of cement

Cement is an indispensable construction material but also one of the most polluting. Its production generates large amounts of greenhouse gasesGreenhouse gases (GHGs) are natural and anthropogenic gases that trap heat in the Earth's atmosphere, regulating the planet’s temperature. However, when ...

Read more such as carbon dioxide (CO2)Carbon dioxide (CO2) is a gas that occurs naturally in the atmosphere and plays a crucial role in the life processes of the planet. This gas, also known as...

Read more, as well as other pollutants like nitrogen oxides (NOx), sulfur dioxide (SO2), chlorides, fluorides, emissions of volatile organic compounds (VOCs), heavy metals, and particulate matter (PM10, PM4, PM2.5, and PM1) which degrade air qualityAir quality refers to the state of the air we breathe and its composition in terms of pollutants present in the atmosphere. It is considered good when poll...

Read more and impact public health. This article analyses the causes, consequences and technologies to mitigate the environmental impact of cement.

Air Quality Innovation in Just 1 Click

Stay informed about the air you breathe!

Subscribe to our newsletter to receive the latest updates on environmental monitoring technology, air quality studies, and more.

Emissions from cement production

Cement production is a significant source of pollutant emissions. The calcination process releases large volumes of carbon dioxide (CO2) due to the decomposition of calcium carbonate. Additionally, the combustion of fossil fuels generates further harmful gas emissions, underlining the importance of applying reduction and control technologies to minimise the environmental footprint.

Primary and secondary pollutants

Cement plants emit both primary pollutants, such as particulate matter (PM10, PM4, PM2.5, and PM1) and gases like NOx and SO2, as well as secondary pollutants that form in the atmosphere, contributing to issues such as acid rain and tropospheric ozone formation. The presence of these fine particles is critical due to their ability to penetrate deeply into the respiratory system.

Cumulative effects on the environment

The atmospheric pollution generated by the cement industry negatively impacts the air quality in surrounding areas, affecting the health of nearby communities and altering local ecosystems. The accumulation and persistence of pollutants in the air require continuous and efficient monitoring to implement effective mitigation strategies and comply with current environmental regulations.

Environmental impact of cement

How polluting is cement production?

Cement production is responsible for approximately 8% of global CO2 emissions, according to a study published by the journal Nature. This impact is mainly due to two key factors: the intensive use of fossil fuels to generate the heat required for manufacturing clinker, the main component of cement, and the chemical reactions that release CO2 during the calcination of limestone, the basic ingredient of clinker.

A study conducted in Ecuador estimated that producing one tonne of cement requires approximately 3,192 MJ of energy and generates emissions of 510.57 kg of CO2. Most of the energy consumption comes from limestone extraction and processing, fuel oil combustion, and electricity use. Clinker production is the unit process with the greatest environmental impact, due to both chemical emissions and fuel consumption.

In addition to CO2 emissions, the cement industry releases particulate matter from combustion, raw material handling, and grinding and storage processes. The World Health Organization (WHO) warns that exposure to fine particles is linked to respiratory diseases, cardiovascular problems, lung cancer, and premature death.

CO2 emitted per tonne of cement

The amount of carbon dioxide emitted varies depending on the technology and fuel used, but typically ranges between 500 and 600 kg of CO2 per tonne produced, with clinker being the main source.

Comparison with other industries

The cement industry is one of the largest industrial CO2 emitters, surpassing sectors such as steel production or electricity generation in certain countries, highlighting the importance of implementing specific control and mitigation technologies.

Trends and future projections

Without technological improvements and stricter regulatory policies, emissions from the sector are expected to continue rising with global cement demand, although innovations in cement emission reduction technologies and increased use of alternative fuels could curb this trend.

What damage can cement cause?

Cement generates negative impacts not only during its production but also throughout its use and final disposal. It affects both natural and urban environments, damaging biodiversity, landscapes, cultural heritage, and people’s quality of life.

A significant consequence is soil sealing, which reduces its capacity to retain water, leading to problems such as runoff, erosion, flooding, droughts, and contamination of surface and groundwater. Cement accounts for nearly 10% of industrial water use, concentrated in regions with water stress.

Another consequence is the alteration of local and global climate, especially due to greenhouse gas emissions and the phenomenon known as the urban heat island, which raises temperatures in cities compared to rural areas due to heat absorption and emission by artificial surfaces like concrete. This affects human health, increases energy consumption, degrades air quality, and threatens biodiversity.

Finally, construction with cement can cause the degradation of cultural and natural heritage, destroying historical, archaeological, and landscape values, and promoting urban homogenisation that loses identity and diversity.

Workers exposed to particulate dust

Effects on human health

Exposure to pollutants emitted by the cement industry has significant consequences for human health. Particulate matter, especially PM2.5 and PM1, can penetrate deeply into the lungs and reach the bloodstream, causing chronic respiratory diseases such as asthma, bronchitis, and chronic obstructive pulmonary disease (COPD). Additionally, inhaling toxic gases such as nitrogen oxides (NOx), sulfur dioxide (SO2), and volatile organic compounds (VOCs) can irritate the respiratory tract and aggravate cardiovascular conditions.

The World Health Organization (WHO) has also linked prolonged exposure to these emissions with an increase in lung cancer incidence and premature mortality. Communities living near cement plants or in densely industrialised urban areas face a higher risk, making rigorous emission control and implementation of technologies that minimise health impacts essential.

Impact on ecosystems and biodiversity

Pollutant emissions from the cement industry severely affect local ecosystems and biodiversity. The release of gases such as sulfur dioxide (SO2) and nitrogen oxides (NOx) contributes to the formation of acid rain, which alters soil and water chemistry, harming flora and fauna. Deposited particulate matter can coat leaves and surfaces, affecting photosynthesis and weakening plants. These environmental changes directly impact organisms dependent on these habitats, reducing biological diversity and causing imbalances in food chains. Furthermore, greenhouse gas emissions contribute to climate change, affecting species distribution and overall ecosystem health. The environmental degradation caused by cement activity endangers sensitive species and limits natural resilience against additional threats.

Social and economic costs

The environmental and health impacts of the cement industry involve significant social and economic costs for communities and governments. Healthcare expenses to treat pollution-related diseases, such as respiratory and cardiovascular problems, increase considerably in affected areas. Moreover, the loss of work productivity due to illness and absenteeism generates a significant indirect cost. Environmentally, the degradation of ecosystems and natural heritage requires investments for restoration and conservation, as well as the loss of vital ecosystem services such as climate regulation and water quality. Governments also face the challenge of implementing and enforcing environmental regulations, requiring technical and financial resources. Lastly, the reputation of industries may suffer, negatively impacting social acceptance and business opportunities, highlighting the importance of investing in sustainable technologies and practices.

However, this manufacturing process, as we describe later, releases pollutant gases and particulate matter that can cause nuisances to the population.

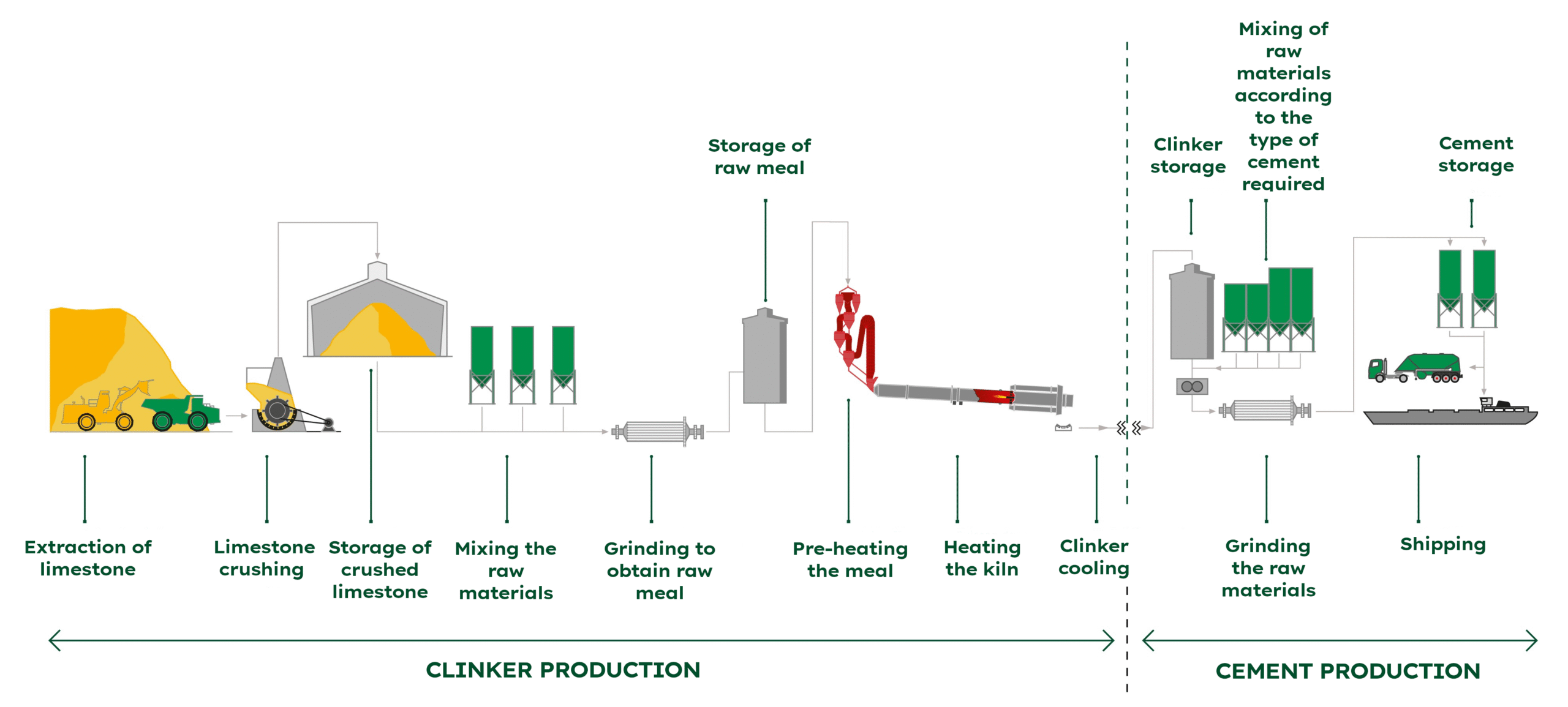

Cement manufacturing process – Source: Heidelberg Materials

Case study: Air quality monitoring at a cement plant

CEMEX, one of the world’s leading cement manufacturers, has developed a proactive policy aimed at anticipating and resolving potential environmental impacts arising from its production activities. To protect both public health and workers’ wellbeing, as well as preserve the natural environment, CEMEX relied on Kunak’s technology to develop an advanced air quality monitoringControlling air quality is an essential task in order to enjoy optimal environmental conditions for healthy human development and to keep the environment i...

Read more system for cement plants.

The chosen solution consisted of installing a perimeter monitoring network at its production plant located in Monterrey, Mexico. This multinational has been making significant investments in sustainability, and this measure represents a continuation of its commitment to local wellbeing and strict compliance with current environmental regulations.

Thanks to innovative technologies such as Kunak AIR Pro, the plant has access to high-quality, precise data that enable better environmental interpretation and informed decision-making. The results are tangible: since 2005, when air quality investments began, until 2019, CEMEX has achieved a significant reduction in emissions, establishing itself as a benchmark in cement emissions control and the promotion of human and environmental health.

Main atmospheric emissions from cement

This case study highlights how technological solutions help prevent environmental issues related to air quality. It is essential to delve into the main atmospheric pollutants associated with the cement industry and their impact.

The most common emissions generated by the cement industry include particulate matter (PM10, PM4, PM2.5, and PM1), nitrogen oxides (NOx), sulfur dioxide (SO2), chlorides and fluorides, volatile organic compounds (VOCs), carbon monoxide (CO)The carbon monoxide (CO) is an invisible gas (colorless and odorless) that, at the same time, is a silent killer because in just a few minutes it exhibits ...

Read more, ammonia (NH3)Invisible yet powerful: ammonia (NH3) is a colourless gas which, although naturally present in the atmosphere in small amounts, can become an unwelcome ene...

Read more, and heavy metals. Each of these pollutants has a specific origin and environmental impact:

PM2.5 and PM10 particles

Particulate matter, especially PM2.5 and PM10, primarily originates from material transportation by trucks and from the chimneys of the kiln system. These particles are particularly concerning due to their ability to penetrate deeply into the respiratory system, increasing the risk of respiratory and cardiovascular diseases among the exposed population. The installation of filters in emissions has significantly reduced this impact.

Carbon dioxide (CO2)

CO2 is the main greenhouse gas emitted by the cement industry, directly associated with the calcination process and the combustion of fossil fuels. Reducing these emissions is key to minimising the sector’s climate impact and moving towards more sustainable production.

Nitrogen oxides (NOx) and sulfur dioxide (SO2)

Nitrogen oxides are produced during high-temperature combustion processes, while sulfur dioxide emissions depend on the sulfur content in raw materials. Both gases contribute to the formation of smogSmog, beyond that dense fog

Smog is a mixture of air pollutantsAir pollution caused by atmospheric contaminants is one of the most critical and complex environmental problems we face today, both because of its global r...

Read more that accumulate in the atmosphere, especially in urban areas. This phenomenon is character...

Read more and acid rain, affecting air quality and environmental health in nearby industrial and urban areas.

Other pollutants

Additionally, the cement industry may release chlorides and fluorides, originating from the raw materials and fuels used, as well as volatile organic compounds (VOCs), carbon monoxide (CO), and ammonia (NH3). These tend to be less significant due to the high combustion temperatures. Heavy metals, present in small quantities, are generally retained in the clinker.

Aerial view of a cement production plant

Carbon footprint: cement’s contribution to global warming

Cement manufacturing not only releases pollutants harmful to human health but is also a voracious consumer of energy, needed to raise the kiln temperature to 1400-1500 ºC. In fact, around 11% of the total energy consumption in the industry is attributed to this sector (2).

In terms of emissions, global cement production accounts for nearly 8% of worldwide carbon dioxide (CO2) emissions (3), highlighting the urgency of implementing effective strategies to reduce its carbon footprint. The carbon footprint measures the total amount of greenhouse gases emitted directly and indirectly by an activity or product, expressed in tonnes of CO2 equivalent.

In the cement industry, greenhouse gas emissions are classified into three scopes to facilitate management and control.

- Scope 1 includes direct emissions from owned sources, primarily combustion in the kilns used to produce clinker. These emissions represent a significant part of the total generated at the plant.

- Scope 2 covers indirect emissions associated with the electricity consumption needed to operate the plant, such as energy used in grinding systems, ventilation, and other auxiliary processes.

- Finally, Scope 3 comprises other indirect emissions related to external activities but linked to cement production, such as transportation of raw materials and finished products, as well as logistics and supply, which also significantly contribute to the industry’s total carbon footprint.

Emission reduction strategies

The cement industry is adopting various strategies to minimise its environmental impact and meet greenhouse gas reduction targets. Among the most effective measures is the use of alternative fuels, including industrial waste and biomass, which reduce reliance on fossil fuels and cut CO2 emissions. Energy optimisation is another key pillar, improving the efficiency of kilns and associated processes through advanced technologies and predictive maintenance.

Additionally, carbon capture and storage (CCS) is emerging as an innovative solution to capture and store CO2 before its release into the atmosphere. Research into new materials, such as low-clinker or ecological cements, also contributes to reducing the carbon footprint.

Finally, continuous monitoring using gas sensors for the cement industry enables more precise and dynamic emissions management, facilitating rapid and effective decision-making to mitigate impacts in real time.

Why monitor air quality in a cement plant?

Air quality monitoring in cement plants is essential to protect the health of workers and nearby communities, as well as to safeguard the environment. Cement plants emit various atmospheric pollutants that can negatively affect air quality, including particulate matter, toxic gases, and compounds that contribute to climate change. Having accurate and continuous detection systems allows for quick responses to critical episodes and compliance with increasingly strict regulations.

Benefits of continuous monitoring

Continuous monitoring offers key advantages such as early detection of pollution peaks, identification of specific sources, and generation of reliable data for decision-making. It helps evaluate the effectiveness of corrective measures and contributes to minimising environmental and health impacts, promoting a safe workplace and harmonious community relations.

Kunak technologies and sensors

Kunak offers advanced sensors specially designed for the cement industry, capable of measuring gases such as methane, nitrogen oxides, sulfur dioxide, ammonia, and particulate matter of various sizes. Their devices include traceable calibration and real-time connectivity, providing precise data centralised on digital platforms that allow detailed analysis and intuitive visualisations.

Regulatory compliance and early alerts

Kunak’s solutions support compliance with environmental standards and facilitate the creation of early warning alerts to prevent pollution episodes. This is crucial to avoid penalties, reduce health risks, and optimise industrial operations sustainably.

Continuous monitoring allows detection and control of cement industry emissions, protecting workers and nearby communities

How to minimise construction’s environmental impact?

Reducing the environmental impact of cement involves several complementary strategies that must be rigorously measured and managed to ensure effective results.

Good practices in construction and logistics

Applying good practices in construction and logistics can reduce fugitive emissions and dust. This includes traffic control, surface wetting, and efficient resource planning to minimise movements and times.

Fuel and raw material substitution

An effective strategy is the replacement of fossil fuels with renewable energies (solar, wind, hydroelectric) and the incorporation of alternative raw materials that reduce clinker content, such as fly ash or geopolymers. These materials, known as hybrid cements, lower the carbon footprint and improve mechanical strength.

Integration with environmental monitoring systems

To validate and control these measures, it is essential to integrate with advanced environmental monitoring systems, such as those offered by Kunak, which allow real-time measurement of emissions behaviour and air quality, facilitating efficient environmental management.

Why is it recommended to monitor air quality around a cement plant?

Cement is a dusty material composed of a mixture of raw materials such as limestone, shale, and marl. Its manufacturing involves intensive industrial processes including extraction, crushing, calcination in high-temperature kilns, and grinding. These operations generate significant emissions of particles and gases that affect air quality.

Rigorous and continuous monitoring allows detecting and controlling these emissions, protecting the health of workers and nearby communities, and ensuring regulatory compliance in a sector with considerable environmental impact.

FAQs about the environmental impact of cement plants

How is air quality measured in cement plants?

Air quality in cement plants is measured using networks of gas and particulate matter sensors that capture pollutants such as PM, nitrogen oxides (NOx), sulfur dioxide (SO2), and volatile organic compounds (VOCs), among others. These systems enable continuous, real-time monitoring, providing precise data for environmental analysis and management.

Which sensors are most effective for detecting particulate matter in cement plants?

The most effective sensors for detecting particulate matter in cement plants are those that measure PM10, PM2.5, and PM1 with high sensitivity and traceable calibration. Equipment such as the Kunak AIR Pro range combines optical and electrochemical technologies to ensure precision in complex industrial environments.

What are the legal emission limits for CO2 and particulate matter?

Legal limits vary according to national and international regulations but typically set maximum levels for CO2 and particulate matter (PM10, PM2.5) emissions to protect public health and the environment. Cement plants must comply with these limits to operate, using control and monitoring systems that facilitate compliance.

How does cement management influence the carbon footprint?

Efficient management of cement production, through reducing clinker usage, optimising energy efficiency, and incorporating alternative fuels, can significantly lower the carbon footprint of cement. Adoption of clean technologies and environmental monitoring are key to measuring and reducing this impact.

What actions can a cement plant take to reduce odours and gases?

To minimise odours and gaseous emissions, cement plants can implement advanced capture and filtration systems, optimise production processes, replace fossil fuels with renewables, and establish continuous monitoring networks to detect and swiftly correct deviations.

Conclusion

Cement is an essential construction material but also one of the most polluting. Its production generates large amounts of CO2 and particulate matter emissions that affect climate, air quality, and public health. Additionally, its use and disposal cause damage to soil, water, heritage, and biodiversity. These emissions are among the main challenges the cement industry must face.

Therefore, it is essential to find ways to reduce the environmental impact of cement, whether by lowering demand, improving production efficiency, or reducing clinker content. This will contribute to more sustainable and environmentally friendly development.

Nonetheless, cement remains fundamental to the advancement of the global economy. Without it, many current infrastructures and developments would be unfeasible.

The true challenge lies in combining economic growth with environmental protection, using best practices and technologies to reduce emissions. Moreover, air quality monitoring will be indispensable to measure progress and ensure a sustainable future.

Sources consulted

- (1) European Environment Agency (2019). EMEP/EEA air pollutant emission inventory guidebook 2019. Technical guidance to prepare national emission inventories. Luxembourg: Publications Office of the European Union, 2019. ISBN 978-92-9480-098-5. Available at https://www.eea.europa.eu/publications/emep-eea-guidebook-2019/part-b-sectoral-guidance-chapters/2-industrial-processes/2-a-mineral-products/2-a-1-cement-production/view

- (2) Kumar Verma, Y., Mazumdar, B., & Ghosh, P. (2020). Thermal energy consumption and its conservation for a cement production unit. Environmental Engineering Research. https://doi.org/10.4491/eer.2020.111

- (3) M. El-Sayed, A., A. Faheim, A., A. Salman, A., & M. Saleh, H. (2021). Introductory Chapter: Cement Industry. Cement Industry – Optimization, Characterization And Sustainable Application. https://doi.org/10.5772/intechopen.95053

- (4) Andrew, R. (2018). Global CO2 emissions from cement production. Earth System Science Data, 10(1), 195-217. https://doi.org/10.5194/essd-10-195-2018

- (5) World Health Organization. (2018). Ambient (outdoor) air quality and health. https://www.who.int/news-room/fact-sheets/detail/ambient-(outdoor)-air-quality-and-health

- Damtoft, J. S., Lukasik, J., Herfort, D., Sorrentino, D., & Gartner, E. M. (2008). Sustainable development and climate change initiatives. Cement and Concrete Research, 38(2), 115-127. https://doi.org/10.1016/j.cemconres.2007.09.008

- García-Lodeiro, I., Fernández-Jiménez, A., & Palomo, A. (2015). Cementos híbridos de bajo impacto ambiental: Reducción del factor clinker. Materiales de Construcción, 65(320), e068. https://doi.org/10.3989/mc.2015.06414

- León-Velez, A., & Guillén-Mena, V. (2020). Energía contenida y emisiones de CO2 en el proceso de fabricación del cemento en Ecuador. Ambiente Construído, 20(1), 77-88. https://doi.org/10.1590/s1678-86212020000100376

- World Economic Forum. (2019). Cement’s CO2 emissions are a big problem. Here are some solutions. https://www.weforum.org/agenda/2019/12/cement-produces-more-pollution-than-all-the-trucks-in-the-world/

- International Energy Agency. (2020). CO2 emissions from cement production. https://www.iea.org/reports/co2-emissions-from-cement-production