1. INTRODUCTION

1.1 About this document

This manual explains how to install, configure and operate the Kunak AIR Pro, an Air Quality Solution for continuously monitor ambient air pollution. All the information, procedures and techniques described in this document are propriety of KUNAK TECHNOLOGIES S.L. The contents of this manual are subject to amendments without prior notice. Please, check the last version available in the support section, on Kunak Cloud.

1.2 Glossary

· Kunak AIR Pro: Device that takes the data from the sensors and transmits it to Kunak Cloud.

· Kunak Cloud: Cloud web platform to consult, analyse data, status of the network, reports.

· API Rest: Way to transmit the data of the Kunak Cloud to another platform.

· S/N: Serial Number.

· P/N: Part Number.

· CO: Carbon monoxide.

· CO2: Carbon dioxide.

· NO: Nitrogen oxide.

· NO2: Nitrogen dioxide.

· O3: Ozone.

· SO2: Sulfur dioxide.

· H2S: Hydrogen sulfide.

· NH3: Ammonia

· VOCs: Volatile Organic Compound.

· PID: Photoionization detector.

· Cartridge slot cap: Cover to protect the cartridge connectors.

· Measurement range: Concentration range measured by the sensor.

· Resolution: Smallest unit of measurement that can be indicated by the sensor

· Temperature range: Interval of temperatures that the sensor could be exposed to.

· RH range: Humidity transients may affect the readings of some sensors reducing their performance.

· Operating life: Lifetime of the sensor in normal conditions. Long exposures to humidity above 85% can damp the sensor and affect the measurements.

· Guarantee range: Limit covered by the guarantee.

· LOD: (Limit Of Detection) Measured at laboratory conditions at 20ºC and 50% RH. The limit of detection is the minimum concentration that can be detected as significantly different at zero gas concentration, based on the metric from the Technical Specification CEN/TS 17660-1:2022..

· Repeatability: Closeness of the agreement between the results of successive measurements of the same measure carried out under the same conditions of measurement

· Linearity: Indicator of the consistency of measurements over the entire range of measurements.

· Performance limit level: Readings below this level can have lower performance than specified. Measured against reference instrument.

· Typical 90% confidence interval: The average of 90% of the hourly measurements obtained in 1 to 8 months field tests between -10 to +30ºC in different countries are below this absolute error comparing to reference instruments.

· Typical precision R²: The average R² obtained between the device hourly measurements and reference instruments for 1 to 8 months field tests between -10 to +30ºC in different countries.

· Response Time: Time needed by the sensor system to reach 90 % of the final stable value.

1.3 Safety Instructions

General safety instructions of the device:

|

|

The Kunak AIR with OPC has a built in OPC that uses an embedded diode laser light source at a wavelength of 658 nm (invisible) and a maximum of 25 mW of power. The OPC is a Class 1 laser product since the user does not have access to the laser source. The user must not open or adjust any parts of the OPC. Removal of the casing may expose the user to Class 3B laser radiation. You must avoid exposure to the laser beam. Do not use if the outer casing is damaged: return to Kunak for inspection. |

|

|

Removal of the external housing exposes the circuitry which contains components that are sensitive to damage by static discharge. Observe precautions for handling electrostatic discharge sensitive devices. |

|

|

This device has built in Li-ion batteries and the user is requested to follow all local and international regulations regarding the handling of such batteries. The batteries are flammable if damaged or punctured. |

|

|

The device is prepared to function and charge the rechargeable batteries supplied by Kunak. Installing any other battery in the device may cause the device to malfunction or even cause damage. |

|

|

This device must be disposed of according to local regulations. We suggest handling it to a specialized electronic recycling facility. |

|

|

Always protect this device from electromagnetic interferences. Strong electromagnetic fields may affect the gas sensors' readings. |

Table 2 – Safety Instructions

2. OVERVIEW

2.1 Description

Kunak AIR Pro is a small, low power consumption device built to remotely measure & control the pollution air concentration of several gases and toxic particles. It provides a wide range of possibilities to maintain and control the environment and the Air Quality. Additionally, it is able to automatically geolocate every sample with an optional built in GPS receiver.

Kunak AIR Pro offers a plug & play solution to keep and manage all your data directly through Internet, thanks to the powerful cloud-based platform Kunak Cloud, where the whole data, alarms, thresholds, remote configuration and calibration capabilities are available through the web interface. Also, a powerful REST API is available to integrate the data into third party applications.

Hence, Kunak AIR Pro Quality Solution is a complete system consisting of hardware (Kunak AIR Pro), wireless communications and a cloud-based software (Kunak Cloud). Advanced proprietary algorithms are running on Kunak AIR Pro device to obtain accurate gas concentration, correcting cross gas effects and environmental conditions.

Kunak AIR Pro can measure up to 5 different gases (per device) with ppb or µg/m³ resolution as well as three particles sizes: <10 µm, <2.5 µm and <1 µm, hereinafter referred as PM10, PM2.5 and PM1. Temperature, Humidity and atmospheric pressure are always measured within the pollutants.

Kunak AIR uses onboard sensors and Kunak embedded algorithm that calculates the concentrations in ppb or μg/m3 locally and in real-time, not using or needing external reference data to calculate gas or particle concentrations.

To get more information about the environment and make more precise conclusions, extra sensors can be installed like an anemometer, pluviometer, sound level meter or WBGT sensors.

Some of the applications in which the device can be used are described in Figure 1 – Kunak AIR Pro applications.

Figure 1 – Kunak AIR Pro applications

To know all the pollutants that a Kunak AIR Pro device can measure, please, contact our commercial team or take a look at www.kunak.es.

Figure 2 – Kunak AIR Pro device

2.2 Key features

· It can measure up to 5 gases and particulate matter at once.

· It can hold up to 5 cartridges which can be easy & fast replaced or combined with others when necessary (no need to unhook the equipment).

· PM1, PM2.5, PM10 particle counting and measurement technology with a total number of particles and particle size distribution.

· (Patent pending) Innovative cartridges system (plug & play replacement). Simply take the old one out and replace it easily with the new one, on the field. Be back online in 2'.

· Every cartridge is individually tested, characterized and factory calibrated to traceable reference standards, with all the information stored on the cartridge to guarantee traceability.

· It is the smallest device on the market with so many parameters that can operate autonomously with only a solar panel, without additional external batteries.

· Temperature, humidity and pressure built in sensors.

· Connect wind, rain, noise, and other sensors.

· Calculation of the AQI

· Intelligent algorithms that compensate for environmental conditions and the aging of the sensor element

· Advanced LCD display to inform the user about the status of the equipment and the sensors.

· Anytime you can plug & play extra environmental sensors thanks to the multiple connectors included in the equipment.

· Multi-Band 2G/3G/4G (LTE-FDD/LTE-TDD/UMTS/HSDPA/HSUPA/HSPA+/GSM/GPRS/EDGE) or Ethernet

· Automatic GPS/Glonass location

· Optionally ModBus

· Extra connections: 4-20 mAh / 0-10V.

· Ultra-low power consumption

· Autonomous operation with its built-in battery and solar panel.

· Compact, rugged & waterproof design IP65 for continuous outdoors operation.

· Long-life rechargeable lithium batteries.

· Easy & Fast installation.

· Access to your data and alarms in real-time.

· Automatic data download to secure server (cloud platform).

· Remote data acquisition system with fail-safe on-board storage.

· Easy integration via API.

· Easy access to data via web.

· Easy calibration: Adjust the baseline and span remotely by the cloud calibration tool.

· Data export, tables and graphs.

· Easy to configure through web or REST API. Remotely configurable access, alerts, thresholds, calibration parameters, reading and transmitting periods and windows.

· Innovative mechanical design. There are NO elements or screws to be lost. All captive, plug & play with a single tool.

· Unibody compact design.

2.3 Technical Data

2.3.1 Mechanical Specifications

|

PROPERTY |

DESCRIPTION / VALUE |

|

|

Device + Solar Shield |

Dimensions |

235 x 270 x 250 mm |

|

Weight |

2.4 ~ 3.4 Kg (depending on configuration) |

|

|

Enclosure |

PMMA & Polycarbonate & Stainless steel |

|

|

Cartridge |

5 sockets for cartridge sensors |

|

|

Connectors |

5x M12 |

|

|

Connector 1 |

M12 x 4 pins female type T |

|

|

Connector 2 |

M12 x 4 pins female type D |

|

|

Connector 3 |

M12 x 5 pins female type B |

|

|

Connector 4 |

M12 x 8 pins female type A |

|

|

Connector 5 |

M12 x 5 pins female type A |

|

Table 3 – Mechanical Specifications

Figure 3 – Device dimensions with solar shield

2.3.2 Environmental Specifications

|

PROPERTY |

DESCRIPTION / VALUE |

|

Operating Temp |

-20 ºC to 60 ºC[1] |

|

Humidity |

0 to 100%RH |

|

IP Rating |

IP65 |

|

Altitude max |

3000 m |

|

Overvoltage category |

Overvoltage category II |

Table 4 – Environmental Specifications

2.3.3 Electrical Specifications

|

PROPERTY |

DESCRIPTION / VALUE |

|

Battery |

Lithium 2.9Ah or 26Ah |

|

External supply |

7 – 12 Vdc (min recommended 12W) |

|

PoE supply |

PoE++ Type 3 |

|

Solar panel supply |

6V, 12W |

|

Autonomy |

Continuous Operation. 24/7 with solar panel or charger |

|

Power consumption |

0.08 to 1.2W depending on the configuration |

|

Communications |

Ethernet or Multi-Band 2G/3G/4G (Bands at 2.5 Communications) |

|

GNSS[2] |

GPS, GLONASS |

Table 5 – Electrical Specifications

2.3.4 Sensors and Proves

|

PROPERTY |

DESCRIPTION / VALUE |

|

Cartridges |

Up to five gas cartridges can be plugged. Each cartridge can carry a CO, NO, NO2, O3, SO2, H2S, CO2 or VOCs sensor. |

|

OPC |

PM1, PM2.5, PM10 particle counting and measurement technology with total number of particles and particle size distribution |

|

Internal status |

Internal temperature, battery level, voltage and current charge, signal level |

|

Environmental built-in Sensors |

Temperature, humidity, atmospheric pressure |

|

Plug & Play extra sensors |

Connector 1: Power Supply 7V to 12V |

|

Connector 2: · K-A3-xx-3: Ethernet PoE. · K-A3-xx-4: Modbus Slave. |

|

|

Connector 3: Sound level meter |

|

|

Connector 4: Modbus Master & (WBGT or Pyranometer) |

|

|

Connector 5: Anemometer & Rain gauge |

Table 6 – Sensors & Proves Specifications

2.3.5 Features

|

PROPERTY |

DESCRIPTION / VALUE |

|

Diagnosis LCD |

Advanced LCD display to inform the user about the status of the equipment and the sensors |

|

Measurement |

Continuous sampling configurable. 3Hz gases, 1Hz particles |

|

Remote management |

Bidirectional configuration of every parameter of the device and sensor network |

|

Low power |

Ultra-low power consumption can be configured for battery length improvement |

|

SIM |

Embedded eSIM and mini-SIM holder |

Table 7 – Features Specifications

2.4 Power Consumption and Duration

The tables below shows the average power consumption of Kunak AIR Pro in the different modes of operation considering a sampling period of 5 minutes and a sending period of 30 minutes.

A low power mode for the OPC (particle sensor) has been designed to enlarge the battery life.

|

Mode of operation |

Battery |

Average consumption |

Average duration[3] |

|

Device On without OPC |

1 Cell –10 Wh |

0.1 W |

70 hours |

|

Device ON with OPC in Low Power |

1 Cell –10 Wh |

0.25 W |

24 hours |

|

Device ON with OPC |

1 Cell –10 Wh |

1 W |

8 hours |

Table 8 – Power consumption

The built in battery has a maximum of 2900 mAh, 10 Wh. To increase battery life and allow 24 hours / 7 days solar panel operation while using the OPC version, the high power rechargeable Li-Ion battery is recommended with a maximum of 26,100 mAh, 93 Wh. In all cases they supply is 3.7 V.

|

Mode of operation |

Battery |

Average consumption |

Average duration[4] |

|

Device On without OPC |

9 Cell – 93 Wh |

0.1 W |

30 days |

|

Device ON with OPC in Low Power |

9 Cell – 93 Wh |

0.25 W |

9 days |

|

Device ON with OPC |

9 Cell – 93 Wh |

1 W |

3 days |

Table 9 – Power consumption with high power pack

Battery durations may last 15% less than specified at the tables above if a VOCs cartridge is connected.

2.5 Communications

Depending on the version acquired, the devices can work with different technologies for transmitting the data to Kunak Cloud or the On-premises server. The amount of data depends on the number of sensors supplied with Kunak AIR device and the sampling period of the sensors, for example for a device configured with a sending period of 5 minutes and a sampling period of 5 minutes, the device will consume less than 10MB/month.

The different technologies of communication can be one of:

· 2G/3G/4G

o LTE-TDD: B34/B38/B39/B40/B41

o LTE-FDD: B1/B2/B3/B4/B5/B7/B8/B12/B13/B18/B19/B20/B25/B26/B28/B66

o UMTS/HSPA+: B1/B2/B4/B5/B6/B8/B19

o GSM/GPRS/EDGE: 850/900/1800/1900MHz

· Ethernet

It is possible to have wired communication Modbus RTU Slave, but it will be combined with the 2G/3G/4G technology to transmit the data also to Kunak Cloud.

2.6 Device Security

Safety is a fundamental factor in all Kunak designs, being implemented from the design of the device to the installation, operation and maintenance, both at a physical level (hardware), as well as software, communications and action protocols.

Thus, this safety protocol begins with the most basic but very important elements, such as the gas cartridges. In this way, each of the cartridges, which store all the test and calibration parameters during the manufacturing process (there can be more than 100) in order to guarantee their traceability and the accuracy of their measurements, incorporates an AES128 encrypted memory to store all this information so that it can only be read by a validated KUNAK station after a series of testing and validation mechanisms of the stored information before the cartridge can be approved.

The device is then initialised against the server, validating its credentials, ensuring that it is a Kunak manufactured device and cannot be supplanted by any other, as in addition to verifying that the device is real, the same is done with all the cartridges connected to it.

Once it starts working, all the measurements are stored in an encrypted internal file system, which is sequentially erased as soon as it is confirmed with the server that it has received all the measurements correctly.

Regarding communications, a fundamental difference is that these are produced asynchronously by the device and are only made against a defined IP (or URL) so that the device has the modem off all the time except when it decides to initiate communication with the defined IP. Only then will it listen for possible configuration messages coming from this IP, correctly encrypted and with their correct codes to the responses made by the device. This prevents communication attempts or attacks on the device from being made when the modem is switched off.

In addition, if the device is working with the electronic e-SIM, a dynamic IP and a private APN (so it is not accessible from the public network), which are another very important layer of security.

Finally, the Kunak devices do not collect any personal information, they only capture, through their sensors, information of the environmental nature or signals to control the device itself (battery, signal level, panel charge, etc.).

In this way, the hardware, electronics, communication and security protocols and communications technologies incorporated in the Kunak AIR make it the most technologically advanced, reliable, robust and innovative product in the world for air quality measurement systems.

2.7 How to Store and Recover Data

Kunak AIR device has been designed to work in very low power consumption mode while the gas sensors are sampled continuously. Every “sampling period”, Kunak AIR will produce a valid reading which is the average of all the valid samples and the time stamp when the averaged has been done. If a sample or reading is considered “invalid” by KUNAK’s proprietary algorithm, it will be invalidated. Every “sending period”, Kunak AIR will send the information wirelessly to the Kunak Cloud and, if the communication is successful, all the measurements will be deleted from the device and stored in Kunak Cloud.

Kunak AIR has an internal flash memory that can store all the readings until the information is sent to the Kunak Cloud. If a communication cycle fails, the readings will be stored in the flash memory until the next successful communication. It is not recommended to set a sending period 500 higher than the sampling periods to guarantee full integrity of information, even with communications failures. Minimum sampling period is set to 10 seconds. Then, when fast readings are desired, for example in mobile applications, a recommend sending period would be between 30min and 1h maximum.

Both, the “sampling period” and “sending periods” are configurable remotely through Kunak Cloud.

Once the information is sent to Kunak Cloud, it is stored in the database and can be recovered through the web interface, exported in .CSV, .TXT formats or through the REST API. Please, refer to the Kunak Cloud manual for more information regarding the cloud-based software and how to analyse, operate and recover data.

Please, note that to start working correctly, Kunak AIR needs to initialize when powered up and make a successful connection to Kunak Cloud before start storing data. So, the user must be sure that there is enough mobile coverage when switching on the device.

|

|

Be aware when analysing data that each sampling period is an average. It is calculated from the last sample to the new one. The average timestamp is set at the end of the sampling time. If the sampling period is 5 minutes, Kunak AIR device will calculate the average, for example, from 12:08 to 12:13 and the timestamp of that measure will be 12:13.

|

In order to offer the data with the maximum possible reliability, the device has a data discrimination mechanism after a connection to the Kunak Cloud to prevent certain electromagnetic interference (EMI) that can alter the data being sampled at that moment. Once the connection is made, the device will discard the following data in the next 2 to 5 minutes. The range of discarded data, variates depending on the sampling period and the sending period configured. The “Sampling period” and the “Sending period” can be changed through Kunak Cloud. An example of how much time the data is discharged (Guard period) regarding the “Sampling” and “Sending period” is shown below.

|

Sampling period |

Sending period |

Guard period |

|

5 mins |

30 mins |

2 mins |

|

10 seg |

30 mins |

5 mins |

Table 10 – Examples of Guard period regarding the Sampling and Sending period

Therefore, if it is desired to have a very small sampling period of e.g. 1 minute, it is recommended that the sending period is large, at least 1 hour, to minimise the number of data that are lost due to the guard period.

3. QUICK START GUIDE

3.1 Package Content

The Kunak AIR Pro is always supplied mounted into the solar shield and with an eSIM preconfigured to work with it. To install and configure a SIM card, please refer to the manual on how to change the SIM card.

|

|

Gas cartridges, probes and power supplies are sent separately. |

Standard Kunak AIR Pro Package:

|

· 1x Kunak AIR + Solar Shield (more information about the version on the label of the box) · 5x Cartridge slot cap (plugged) · 1x Particle sensor cover kit[5] · 1x Wall or mast mounting kit · 1x Stainless steel hose clamp · 1x Allen key 4 mm · 1x Quick start guide |

|

If any damage has been produced during transport, please, contact KUNAK or your local distributor.

3.2 Required Tools and Equipment

To install the Kunak AIR Pro, you need the following tools:

· 4-mm Allen Key (provided).

· (For mast installation) Screwdriver or 6 mm socket wrench.

· Cutter for the stainless-steel hose clamp.

· (For wall installation) Screwdriver and 4 bolts (minimum 2).

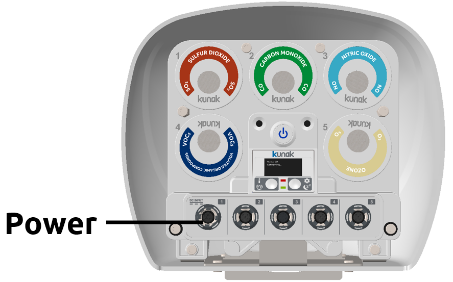

3.3 Parts of a Kunak AIR Pro Station

Figure 4 – Parts of a Kunak AIR Pro

|

1. Inlet Particle sensor 2. Support holder 3. Outlet Particle sensor 4. Metallic grid 5. Solar Shield 6. External Temp, Humidity, pressure and dew point sensors |

7. Cartridge 8. Power button 9. Connectors for power and optional probes 10. LCD display 11. Display Buttons 12. LEDs indicators |

3.4 Power On/Off Button

Please note that the button cuts off all power to the device so that the gas sensors are no longer powered and will have to be restabilised when powered on.

|

|

|

3.5 LEDs Indicators and Display Buttons

The LEDs below the display indicate the current status of the device.

|

|

|

There are two buttons below the LCD that will change the LCD messages. To access the functionality of the buttons, for the upper symbols briefly press the button, and for the lower symbols, press the button for 5 seconds.

|

|

|

3.6 Installation of the Smart Gas Cartridge

|

|

The VOCs sensor cartridge ionises ambient air generating small amounts of O3, so avoid installing it near O3, NO2 or SO2 sensors. For example, place the VOCs sensor in slot 5 and the O3, NO2 and SO2 sensors in slots 1, 2 and 4; avoid placing them in slot 3. |

The cartridge can be installed at any slot of the Kunak AIR Pro device (always with the device switched off). When is turned ON, the device will automatically detect the cartridge and its position showing them at the LCD display. The positions are:

Figure 5 – Cartridges position

3.7 Pluggable Probes or Extra Sensors

There are 5 plugs at the bottom of the Kunak AIR Pro device to connect the power and extra sensors. Each M12 plug is different and only fits its specific connector.

The probes or extra sensors can be plugged to the Kunak AIR Pro device in every moment and some of them depends on the characteristics chosen at the purchase time. The probes will be automatically detected at start-up of the device. The features of each connector are:

· Connector 1 (M12 x 4 pins type T): Power 7V to 12V.

· Connector 2 (M12 x 4 pins type D):

o K-A3-xx-3: Ethernet PoE.

o K-A3-xx-4: Modbus Slave.

· Connector 3 (M12 x 5 pins type B): Sound Level Meter.

· Connector 4 (M12 x 8 pins type A): Modbus Master & (WBGT or Pyranometer).

· Connector 5 (M12 x 5 pins type A): Anemometer & Rain Gauge.

Figure 6 – Probes position

3.8 Checking Before Deployment

|

|

Be aware while installing a cartridge or a probe sensor. · The Kunak AIR device must be powered OFF while plugging/unplugging a cartridge or probe. If the device is powered ON while doing the change, it can damage the sensor or the Kunak AIR Pro station. Press firmly on the cartridge. · Be careful while inserting the cartridges into the device, the pins may bend if the cartridge is not inserted perpendicularly. · If a SIM card is going to be installed, please go to “Install or Change the SIM card” section of the Kunak AIR Pro User Manual. |

Before placing the base station in the final location, it is recommended to connect the cartridges and probes to test the correct function of the station in the office.

The steps to properly test the device prior to deployment are described below. The device will be factory configured being ready to start working.

|

|

Video tutorial of the steps described below |

|

1 |

Remove the metallic grid cartridge protector by loosening the bolts and sliding the protector forward. |

|

|

2 |

Plug the cartridges of your choice into the device.

|

|

|

3 |

Plug all the probes that will be installed at the final deployment by removing the cover of the connector in which the probe will be mounted. Do not remove covers from connectors that are not going to be used. |

|

|

4 |

Keep the cartridge covers and the connectors protectors of the probes in the cartridges box for future use. |

|

|

5 |

Press the power ON button (the button must be held down) and check on the display that the device detects all the cartridges (on its position) and probes. If any sensor is not detected, verify that it is properly connected. |

|

|

6 |

Mount the metallic grid cartridge protector and tighten the two bolts. Put the device at stand-by or power OFF depending of your needs. |

|

3.9 Location Selection

Selecting a location depends on the final application, road traffic monitoring, urban background, etc. However, the user should have the following considerations when selecting the final location:

|

|

Install the device far away from very close pollution sources and without enough air flow (chimneys, air conditioners, etc), that may disturb your readings. If a sonometer is also going to be placed, install it in a place with low wind impact, avoiding vibration sources and avoiding electromagnetic sources. |

|

|

Install the unit between 3 and 4 meters high. |

|

|

If the unit is installed with solar panel, locate the devices far away from buildings, trees, etc…. to be sure that the solar panel receives maximum solar radiation to guarantee a correct battery recharge. Otherwise, Kunak AIR Pro will run out of battery. |

|

|

if the device is installed with a solar panel in the North hemisphere, the solar panel must face to the South, and to the North in case of the South hemisphere. |

3.10 Installation to Mast or Wall Mount

The Kunak AIR Pro device must be mounted in a determined way due to some design restrictions.

The fixed Kunak AIR Pro model should be mounted with the five cartridge sensor holes facing down and the Kunak AIR Pro sticker facing to the front.

The steps to install the Kunak AIR Pro to a wall or mast are described below. The device is delivered completely mounted into the solar shield.

Different types of possible installations: vertical mast, horizontal mast or wall. The minimum mast diameter on which the device can be hung is 3cm.

|

|

Video tutorial of the steps described below |

|

|

|

|

|

Vertical mast |

Horizontal mast |

Wall |

Figure 7 – Types of possible installations

|

1 |

Place the base of the support on a wall or mast. |

|

|

2 |

Place the support to the base with the two bolts. |

|

|

3 |

Place the device inside the support through the groove. |

|

|

4 |

Screw the two captive fixing bolts. |

|

|

5 |

Connect the power connector and the probes. Screw the probes connectors all the way in.

|

|

|

6 |

Power ON the device returning from “stand-by” by pressing the sleep button or by pressing down the power ON button. |

|

Table 11 – Installation steps

Note: Once

the device is working normally, the status of all sensors, battery, charge and

connection can be checked by pushing the ![]() button.

button.

3.11 Storage and Transportation

There are some aspects to consider if the Kunak AIR Pro device is going to be stored or transported to change of location.

Before uninstalling the device, turn it off.

1.

Push the sleep button ![]() for

5 seconds.

for

5 seconds.

2. LCD will show that is sending the last data.

3. Wait until the LCD and the LEDs are off.

To avoid the stabilization period of the gases sensors, let the device at Stand-by mode. If it is going to be stored long period of time, with the device in stand-by:

4. Un-press the power button (it must rest at the same level that the LCD).

5. Unplug the gas cartridges.

6. Store them at the antistatic bag provided.

7. Plug the cartridge covers to the device.

8. Put the covers on the connectors.

It is very important that the power button is un-pressed before transportation or storage for long period of time. This ensures that the internal battery power is not connected.

3.12 Kunak Cloud Account

When purchasing a Kunak AIR Pro device an email with initial User account and Password of Kunak Cloud (www.kunakcloud.com) is sent. If no user account has been sent, please contact your distributor or KUNAK.

Only an Admin account can create new accounts if free items are available. Check the user manual of Kunak Cloud to get more info.

3.13 Verification of the Correct Functioning

On the Kunak AIR Pro start-up, follow the LCD display info to know that all the sensors are detected by the device and it is correctly connected to the Kunak Cloud. This procedure can last up to 5 minutes.

Figure 8 – LCD display help knowing what has detected the device

Also, it is recommended to wait for the first data to arrive on the Kunak Cloud platform. See the figure below to find the last connection time.

Figure 9 – Last connection time in Kunak Cloud

The device must turn green or yellow (with warnings) indicating that is connected and checking the “last connection time”. It can be read when the last connection was made.

Once the device has successfully connected to the cloud, it sends one measurement to Kunak Cloud before start working at the configured sampling and sending periods. These values can be checked in the dashboard. If the device has been switched off for a long time or the battery has been disconnected, the sensors may require several minutes (between some minutes several hour) till the cartridges reach the working conditions. If the values send by Kunak AIR Pro while the sensors are stabilizing are out of range, the Cloud platform will invalidate these values.

Then, it is recommended to wait a from 2 hours to 24 hours (depending on the sensor) after the first initialization to check the sensor readings. Every Kunak AIR Pro has been factory pre-calibrated before shipping to guarantee the best accuracy as possible during initial deployments. However, a final local calibration may be required to reach the best performance of the sensors.

While Kunak AIR Pro is turned ON and after switching it OFF, the user can access to Kunak Cloud to check the data, connections, health of the devices, sensor readings, etc. Please, check that sensors readings, battery and signal values, charge, etc. are within expected ranges to detect any anomaly.

Kunak AIR Pro must communicate its values to Kunak Cloud, but sometimes a connection may fail. In these cases, the devices will store all the readings till a successful connection is achieved.

If the device status is “OFF” or “OFFLINE” in Kunak Cloud, wait until the next connection period and/or check its last battery value. When the installation has been made under very low signal levels, (<-90dBm), the number of failed connections could be higher than desired, but no data should be lost.

|

|

Be aware when analysing data that each sampling period is an average. It is calculated from the last sample to the new one. The average timestamp is set at the end of the sampling time. If the sampling period is 5 minutes, Kunak AIR device will calculate the average, for example, from 12:08 to 12:13 and the timestamp of that measure will be 12:13.

|

In order to offer the data with the maximum possible reliability, the device has a data discrimination mechanism after a connection to the Kunak Cloud to prevent certain electromagnetic interference (EMI) that can alter the data being sampled at that moment. Once the connection is made, the device will discard the following data in the next 2 to 5 minutes. The range of discarded data, variates depending on the sampling period and the sending period configured. The “Sampling period” and the “Sending period” can be changed through Kunak Cloud. An example of how much time the data is discharged (Guard period) regarding the “Sampling” and “Sending period” is shown below.

|

Sampling period |

Sending period |

Guard period |

|

5 mins |

30 mins |

2 mins |

|

10 seg |

30 mins |

5 mins |

Table 12 – Examples of Guard period regarding the Sampling and Sending period

Therefore, if it is desired to have a very small sampling period of e.g. 1 minute, it is recommended that the sending period is large, at least 1 hour, to minimise the number of data that are lost due to the guard period.

4. OPERATION

4.1 Overall Performance

When a Kunak AIR Pro device is installed in a location and switched on, it starts measuring pollutants in the environment depending on the installed sensors. Each sampling period, the device will save the values of the sensors and store them until the next communication to the Kunak Cloud.

The data is sent through the internet by the 2G/3G/4G telecommunication to our cloud server. Then the data can be analysed by the Kunak Cloud platform, Kunak Watcher android app or by API REST.

Figure 10 – General operation of the devices

4.2 Power On Procedure

Before switching on the device, the user must take into account that:

· All the cartridges and probes are mounted. If they are connected while the device is working, they would not be detected and can damage the sensor and the device.

· To start taking measurements the device has to be installed in a place with enough mobile coverage or internet connection or at least with GPS coverage. In case none of the previous conditions are met please check the warning note at section 4.4 Kunak AIR Pro will not start storing data until it acquires a valid timestamp to tag the datapoints.

The Kunak AIR Pro is factory configured to communicate with the platform directly, no further configuration is required by the user. The cartridge and probes connected to the device are autodetected during initialisation, no configuration is needed.

By pressing the power button, the device

will start working. If the button is pressed, and when pressing the info button

![]() , no information is

shown in the display and no LED blinks, the device is at Stand-by. Please check

the Sleep procedure in section 4.5 Power off Procedure.

, no information is

shown in the display and no LED blinks, the device is at Stand-by. Please check

the Sleep procedure in section 4.5 Power off Procedure.

When the device boots follow these steps:

1. Kunak logo is displayed.

2. If a USB is connected, the initialisation will be blocked waiting for the device configuration program to be finished or for disconnecting the USB.

3. If the device has insufficient battery power, this will be indicated on the display. The device will be set in sleep mode until the battery is sufficiently charged. When the battery is charged, the device will start the process again automatically.

4. All sensors connected to the device are shown on the display. Verify that all cartridges and probes are detected, if not, switch off the device, check the connections and start again.

5. The device will try to connect for the first time to the Kunak Cloud to achieve a valid timestamp and send the settings. The first values from all sensors will also be sent to the Kunak Cloud in order to verify that everything is working correctly.

6. When the first communication is successfully completed, it will be displayed on the screen. If any error occurs, the error will be indicated.

7. If the device fails to connect to the Kunak Cloud it will try to achieve a valid timestamp though GPS or it will check if it has a valid timestamp stored in its non-volatile memory. In case of success the device will start to operate in datalogger mode. In case of failure the device will return to step 5.

8. The first 30 mins after the start-up, the device will connect to the cloud automatically every 5 minutes to send the first data in order to confirm the correct working of the device.

9. After the first 30 mins, the device will start working normally as configured (with the sending period, sampling period and options configured).

|

|

Kunak Cloud will auto-invalidate the first data points after the device starts. To prevent a wrong analysing of the data points of the device pollutants, the cloud auto-invalidate the readings after it start working. The range of invalidated data varies depending on how long the device has been switched off. |

4.3 Measurement mode

The device takes measurements each sampling period and sends the data to the Kunak Cloud each sending period. The sampling and sending period can be changed remotely at Kunak Cloud.

The time (timestamp) at which the device collects or sends data is defined by the time at which the device starts working. For example, if the device starts to operate at 12:03 and is configured to collect and send data every 5 minutes, there will be data at 12:08, 12:13, 12:18, etc. This starting time cannot be changed. Please note that there may be delays due to communication errors.

Sampling

The Kunak AIR Pro will store data from the different sensors at the configured sampling period. When data is saved, the green LED will blink.

|

|

Be aware when analysing data that each sampling period is an average. It is calculated from the last sample to the new one. The average timestamp is set at the end of the sampling time. If the sampling period is 5 minutes, Kunak AIR device will calculate the average, for example, from 12:08 to 12:13 and the timestamp of that measure will be 12:13.

|

In order to offer the data with the maximum possible reliability, the device has a data discrimination mechanism after a connection to the Kunak Cloud to prevent certain electromagnetic interference (EMI) that can alter the data being sampled at that moment. Once the connection is made, the device will discard the following data in the next 2 to 5 minutes. The range of discarded data, variates depending on the sampling period and the sending period configured. The “Sampling period” and the “Sending period” can be changed through Kunak Cloud. An example of how much time the data is discharged (Guard period) regarding the “Sampling” and “Sending period” is shown below.

|

Sampling period |

Sending period |

Guard period |

|

5 mins |

30 mins |

2 mins |

|

10 seg |

30 mins |

5 mins |

Table 13 – Examples of Guard period regarding the Sampling and Sending period

Therefore, if it is desired to have a very small sampling period of e.g. 1 minute, it is recommended that the sending period is large, at least 1 hour, to minimise the number of data that are lost due to the guard period.

Sending data to Kunak Cloud

For each configured sending period, the device will attempt to connect to the Kunak Cloud to send all data stored in the device. If the device fails to transmit the data, the data will be stored until the next sending period or until the memory reaches its maximum by overwriting the first data measured (FIFO).

While the data is sent to the Kunak Cloud, the equipment stops storing samples because of electromagnetic interferences that affect the sensor measurements.

During the whole process of communication with the Kunak Cloud, the green LED will remain on.

The data sending process can take between 1 to 5 minutes depending on the amount of data to be sent.

Information display

While the device is running, the status of

the device and the latest measured values can be watched by pressing the

information button ![]() . By pressing the info

button, all data will be automatically displayed on the screen. When finished,

the display will turn off again.

. By pressing the info

button, all data will be automatically displayed on the screen. When finished,

the display will turn off again.

The display will remain off if the button is not pressed in order to save the device's battery.

4.4 Sleep Mode Procedure

Recovering the device from sleep mode

The Kunak AIR Pro is in sleep mode

if the power button is pressed in, the green LED does not light up and pressing

the info button ![]() does not activate the

display.

does not activate the

display.

To return from sleep, press and hold the

sleep button ![]() until the display

turns on. The display will indicate the processes that the device is going on.

When it has finished to show the messages, it will return to the normal working

state.

until the display

turns on. The display will indicate the processes that the device is going on.

When it has finished to show the messages, it will return to the normal working

state.

Switching the device to sleep mode

It is recommended to switch the device to stand-by in the following cases:

· Before switching off the device completely, so that the last data is sent to the Kunak Cloud.

· When the device is going to be relocated but the gas sensors are powered so they do not have to be stabilised again.

· When the device will be started in a remote location without cellular and GPS coverage (i.e: tunnels, mining facilities) to store a valid timestamp inside the device non volatile memory that will allow it to operate when started later on in a place without cellular and GPS coverage.

To put the device on stand-by, follow the steps below:

1.

Press and hold the sleep button ![]() for 5 seconds.

for 5 seconds.

2. The device will ask to confirm that the user wants it to enter in sleep mode.

3. Confirm or deny by pressing the button below the YES or NO sentences on screen.

4. Once confirmed, the display will show that the equipment is performing the last actions before entering sleep mode. It will take the last sample and send all the data stored so far to the Kunak Cloud.

5. Wait until the sleep process finishes. The display and the LEDs will switch off.

The device will turn off the display and LEDs and will not respond to any keystrokes until the process of returning from stand-by is started.

|

|

Important notice for installations in locations without cellular and GPS coverage. To properly operate and to be able to take measurements Kunak devices need to have a valid timestamp to tag the data points in a timescale. To achieve such timestamp the device tries to connect to Kunak Server and in case of failure it tries to get it through GPS. If a device will be installed in a location where neither of the two options above will succeed, there is a third option available: the device must be started in a location where cellular coverage is available to allow it to get a valid timestamp then once the timestamp has been achieved the device must be put in sleep mode. In sleep mode the timestamp timer is still running. Now the device (still in sleep mode) can be installed in the required location and as last step it MUST be woken up from sleep mode with the proper procedure described above. When waking up from sleep the device will update its valid timestamp and therefore it will be able to start operating in measurement mode even in locations where cellular and GPS coverage are not available. |

4.5 Power off Procedure

The device can be switched off directly from the shutdown button, but the last data will not be sent to the Kunak Cloud platform and the latest valid timestamp will not be stored in device’s non-volatile memory. For all data to be sent to the platform before the device is switched off, the device must be put into stand-by mode (See 4.4 Sleep Mode Procedure).

Once the device is in sleep mode,

press the power off button ![]() and store

the device according to the Storage and Transportation procedure.

and store

the device according to the Storage and Transportation procedure.

4.6 Power Saving

|

|

Only available when the device is equipped with the particulate sensor (OPC). The OPC (Optical Particle Counter) consumes a lot of battery of the Kunak AIR Pro device and therefore the power saving option can be enabled. |

In order to save the device's battery and to keep it on longer, there is a low power mode that can be activated. This mode is mainly intended for devices that are going to be without power for a prolonged period of time, such as devices connected to a solar panel or in places where power cuts are common.

When the device is in this mode, it only affects the particle sensor as it is the element that has the highest power consumption since it has to operate a fan.

To enter this mode, the device must be configured via the Kunak Cloud or the REST API. Through the Kunak Cloud, in the configuration section of the device, there is a section called "Power Saving" for the "Particle sensor" and it must be at "Low power". In brackets can be seen the current status of the device.

Figure 11 – Power saving

· Low power: the device ignores the sampling period for the particulate sensor and starts sampling every 10 minutes. The rest of the sensors are not affected. The particle sensor will be off for 9 minutes, turn on for 1 minute, save the average of samples for that minute, and turn off again. In this mode, the battery life of the device is prolonged. See 2.4 Power Consumption and Duration.

· High power: the particle sensor will work the same as all other sensors and all the restrictions of the “low power” will not apply.

4.7 Clock

The time is provided to the device by several means depending on the available mobile/internet connection and the GPS coverage when it is switched-on. Primarily the device tries to acquire a valid timestamp from Kunak Cloud, if not possible it checks if a valid timestamp has been stored into its non-volatile memory ( as described in section 4.4) and at last it tries to achieve it through GPS The data is always stored in the device with a timestamp in UTC and then the Kunak Cloud corrects the time based on the time zone configured for the device. Therefore, the device will not start taking measurements until the time has been updated at start-up.

The only exception is when the device is a Modbus Slave. In this case measurements will be available on the bus even if the device couldn’t achieve a valid timestamp but timestamp registers will not be meaningful.

In order to keep the timestamp data as accurate as possible, the device time is refreshed once every 7 days.

To better understand how the device operates depending on the mobile available mobile/internet/GPS coverage please check the following state flow.

.

4.8 Sampling period and Timestamp

Then, it is recommended to wait a couple of hours after the first initialisation to check the sensor readings. Every Kunak AIR Pro has been factory pre-calibrated before shipping to guarantee the best accuracy possible during initial deployments. However, a final local calibration may be required to reach the best performance of the sensors.

While Kunak AIR Pro is turned on and after switching it OFF, the user can access to Kunak Cloud to check the data, connections, health of the devices, sensor readings, etc. Please, check that sensor readings, battery and signal values, charge, etc. are within expected ranges to detect any anomaly. In order to know typical ranges, go to 5 SENSORS.

Kunak AIR Pro must communicate its values to Kunak Cloud, but sometimes a connection may fail. In this case, the device will store all the readings till a successful connection is achieved. Then, if the device appears in “red colour” in Kunak Cloud, wait until the next connection period and/or check its last battery value. When the installation has been made under very low signal levels, (<-90dBm), the number of failed connections could be higher than desired, but no data should be lost.

|

|

Be aware when analysing data that each sampling period is an average. It is calculated from the last sample to the new one. The average timestamp is set at the end of the sampling time. If the sampling period is 5 minutes, Kunak AIR device will calculate the average, for example, from 12:08 to 12:13 and the timestamp of that measure will be 12:13.

|

In order to offer the data with the maximum possible reliability, the device has a data discrimination mechanism after a connection to the Kunak Cloud to prevent certain electromagnetic interference (EMI) that can alter the data being sampled at that moment. Once the connection is made, the device will discard the following data in the next 2 to 5 minutes. The range of discarded data, variates depending on the sampling period and the sending period configured. The “Sampling period” and the “Sending period” can be changed through Kunak Cloud. An example of how much time the data is discharged (Guard period) regarding the “Sampling” and “Sending period” is shown below.

|

Sampling period |

Sending period |

Guard period |

|

5 mins |

30 mins |

2 mins |

|

10 seg |

30 mins |

5 mins |

Table 14 – Examples of Guard period regarding the Sampling and Sending period

Therefore, if it is desired to have a very small sampling period of e.g. 1 minute, it is recommended that the sending period is large, at least 1 hour, to minimise the number of data that are lost due to the guard period.

4.9 Auto Geo-position

When Kunak AIR Pro is started, it takes the location via GPS and sends it to the platform. Once the location is sent, it will not send again unless the device is restarted or requested from the Kunak Cloud.

In this way, the location of the device can be identified and displayed on the Kunak Cloud map.

The geo-position could fail if the device is indoors, or if it has been moved to another location without restarting. For these cases, the device can be re-requested to send its position via Kunak Cloud in the "Configuration > Device > Location” section and clicking at the button “Require GPS position".

The device may take a while to geo-position itself while collecting satellite data, be patient.

4.10 Auto Invalidation of data points

In order to avoid the analysis of incorrect data points, in some cases the Kunak Cloud is able to detect such incorrect data and auto-invalidate them. When a data point is invalidated, it is not deleted but the flag is changed from temporary (T) to temporarily invalid (TI).

This is the case, for example, of the initial stabilisation period of the sensors, broken sensor, invalidation of particles due to fog or many other auto-invalidations. The types of flags and the table of automatic invalidations can be found in the Kunak Cloud User Manual.

4.11 Communication by 2G/3G/4G

By default, the device is shipped with a multioperator eSIM (embedded SIM on chip) already installed, configured and ready to operate. At the time of communication, the Kunak AIR Pro device will choose the carrier with the best coverage for the location you are in.

|

|

The eSIM supplied with the device can work in almost all countries. To ensure that it works in your country, please contact your distributor or Kunak. |

In case it is required, the Kunak Air Pro device offers the possibility of inserting an external SIM card. In order to make the device work with the external SIM card it MUST be configured with the new SIM parameters. At any time, the device can be re-installed with the Kunak eSIM by simply removing the external SIM card from its dedicated slot.

4.12 Install or Change the external SIM card

|

|

CAUTION: Inserting a new external SIM into the device or changing the one already inserted in it requires the change of the SIM PIN and APN. · To change the SIM PIN, APN, APN user or APN password, the software “Kunak Device Configurator” MUST be used. The software and the user manual of the “Kunak Device configurator” can be downloaded from the Support area of Kunak Cloud. |

By default, the Kunak AIR Pro is shipped with an eSIM card installed and configured. This is a global multi-operator eSIM card that cannot be removed from the device. With the eSIM, at the time of communication, the Kunak AIR Pro device will choose the carrier with the best coverage for the location you are in.

If it is needed, a Mini-SIM (form factor 2FF, 25mm x 15 mm) card can be installed. In this case, the device must be open to install the mini-SIM and update the PIN and APN configuration of the SIM that has been installed.

The Kunak AIR Pro device will communicate through the eSIM if there is no mini-SIM card inserted. When a mini-SIM card is inserted into the external sim slot, the device will detect it and will always work through the external SIM instead of the embedded eSIM. Therefore, it MUST be ensured that whenever a mini-SIM card is inserted, the device is correctly configured to make the external SIM work.

The following steps describe how to insert an external SIM into a Kunak AIR Pro device.

Figure 12 – Location of the mini-SIM card and USB configurator

|

1 |

The device must be switched off before starting the process. |

|

|

2 |

Remove the solar shield from the device by unscrewing the 2 screws and pulling it out. |

|

|

3 |

Unscrew the 4 screws on the top cover of the device to open the upper half of the device. |

|

|

4 |

Open the SIM card holder by sliding the metal part to the left (as in the picture). |

|

|

5 |

Insert the mini-SIM card by sliding it into the SIM card holder. |

|

|

6 |

When the mini-SIM is inserted, close and look the SIM card holder by sliding the metal part to the right (as in the picture). |

|

|

7 |

Connect the mini-USB cable to the connector and the PC. |

|

|

8 |

Once is connected to the PC, switch on the device. |

|

|

9 |

Wait until “DEVICE READY FOR USB CONFIGURATION” appears on Kunak Air Pro screen. |

|

|

10 |

The device is ready for USB configuration, please follow the instructions bellow to set external SIM configuration parameters to the device through Kunak Device Configurator application. |

|

|

11 |

When the configuration is finished, disconnect the USB, switch off the device and follow the instructions in reverse to reassemble the device. |

|

Table 15 – Install or change of SIM card

To make the external SIM work properly, its PIN and APN parameters MUST be configured and stored into the Kunak AIR device. To do so, Kunak provides a Windows application (Kunak device configurator) that can be downloaded from the Kunak Cloud support section. Once the application has been properly installed, the Kunak AIR device can be connected to the PC through an USB cable in order to be configured by Kunak Device Configurator application.

First, open Kunak Device Configurator application and wait for it to recognize the COM PORT where the device is connected. Once the COM PORT has been displayed in the application window, insert the device PIN to enable Kunak Device Configurator application and click “Next”.

Figure 13 – Device configuration: Detecting devices

Then, Kunak Device Configurator application will show the device’s home page where device name, pin and time zone configuration can be edited if needed. Skip to the SIM and Cellular Communication configuration window by clicking next.

Figure 14 – Device configuration: node

In case your external SIM requires a PIN in order to enable communication, configure it in the “SIM PIN” field, otherwise leave the field as it is.

Figure 15 – Device configuration: PIN

Once in the SIM and Cellular Communication window, set your specific external SIM configuration parameters in the “SIM APN”, “APN user” and “APN password” fields.

![]() Search for the APN configuration of your operator over internet.

Search for the APN configuration of your operator over internet.

Figure 16 – Device configuration: Connection

Once all external SIM parameters have been properly configured, by clicking “Next”, the Kunak Device Configurator will launch a Communication Test where the device will try to connect to Kunak Cloud server to verify that cellular communication works properly. This test may take up a few minutes to complete. If the SIM has been properly configured the test will succeed and the device is ready to operate, otherwise please check the error code displayed by Kunak Device Configurator and go back to the SIM configuration window to check the external SIM configuration.

Figure 17 – Device configuration: node status

To store the configurations into Kunak Air Pro device and start normal operation, please skip through the Kunak Device Configurator windows by clicking “Next” until you reach the end.

4.13 Local USB configuration

The device can be configured remotely at any time via Kunak Cloud. If necessary, it can be configured via USB and a Windows application (Kunak device configurator) that can be downloaded from the Kunak Cloud support section.

It is needed a mini-USB cable to connect the device to the PC.

|

1 |

The device must be switched off before starting the process. |

|

|

2 |

Remove the solar shield from the device by unscrewing the 2 screws and pulling it out. |

|

|

3 |

Unscrew the 4 screws on the top cover of the device to open the upper half of the device. |

|

|

4 |

Connect the mini-USB cable to the connector and the PC |

|

|

5 |

Switch on the device and follow the instructions of the “device configurator manual”. |

|

|

6 |

When the configuration is finished, disconnect the USB, switch off the device and follow the instructions in reverse to reassemble the device. |

|

Table 16 – USB configuration procedure

4.14 Kunak Cloud

The Kunak AIR Pro device has been designed to work with a powerful cloud platform Kunak Cloud. Remote configurations, calibration, analytics, etc... can be done from this powerful software. Please, download the “Kunak Cloud WEB” manual to explore all the software capabilities from the “support” section in your Kunak Cloud account (up-right).

Figure 18 – Kunak Cloud support section

5. SENSORS

The Kunak AIR Pro device takes measures continuously of each sensor. The mean value of each sampling period (configured in Kunak Cloud) is stored. The frequency of the measures variates depending on the sensors:

|

Sensor |

Frequency |

Seconds |

|

Internal sensors |

Sampling period configured |

Sampling period configured |

|

Environmental sensors |

Sampling period configured |

Sampling period configured |

|

Gases |

3 Hz |

0.2 s |

|

Particles |

0.3 Hz |

3 s |

|

Noise |

8 Hz |

0.125 s |

Table 17 – Frequency of the sensors

Those samples can be accessed through Kunak Cloud platform, Kunak Watcher mobile application or integrated into other systems via the REST API. Please refer to Kunak Cloud User Manual or the Kunak API User Manual for instructions on how to proceed.

|

|

Be aware when analysing data that each sampling period is an average. It is calculated from the last sample to the new one. The average timestamp is set at the end of the sampling time. If the sampling period is 5 minutes, Kunak AIR device will calculate the average, for example, from 12:08 to 12:13 and the timestamp of that measure will be 12:13.

|

In order to offer the data with the maximum possible reliability, the device has a data discrimination mechanism after a connection to the Kunak Cloud to prevent certain electromagnetic interference (EMI) that can alter the data being sampled at that moment. Once the connection is made, the device will discard the following data in the next 2 to 5 minutes. The range of discarded data, variates depending on the sampling period and the sending period configured. The “Sampling period” and the “Sending period” can be changed through Kunak Cloud. An example of how much time the data is discharged (Guard period) regarding the “Sampling” and “Sending period” is shown below.

|

Sampling period |

Sending period |

Guard period |

|

5 mins |

30 mins |

2 mins |

|

10 seg |

30 mins |

5 mins |

Table 18 – Examples of Guard period regarding the Sampling and Sending period

Therefore, if it is desired to have a very small sampling period of e.g. 1 minute, it is recommended that the sending period is large, at least 1 hour, to minimise the number of data that are lost due to the guard period.

5.1 Internal Sensors

All the internal sensors will be always supplied with a Kunak AIR Pro device.

5.1.1 Device status sensors

All Kunak devices come with built in sensors to monitor internal device status. Those sensors are:

|

Sensor |

Description |

|

Battery (%) |

Device battery percentage. |

|

Charge (V) |

Voltage provided by the charger. |

|

I_Charge (mA) |

Current provided by the charger. Only available at devices with operation package. |

|

Signal (dBm) |

Mobile coverage of the device |

|

Temp |

Internal temperature of the equipment. Only available at devices with operation package. |

Table 19 – Device status sensors

The Battery sensor gives measures of the battery voltage. With rechargeable batteries, those measures should range between 4.1 volts (100%) when fully charged and 3.4 V (1%) when nearly empty. At 3.4 V (1%), the device will automatically switch off to protect the battery life, but the sensors will rest powered to prevent its destabilization. Kunak AIR Pro will automatically switch on when 3.45 V (11%) is reached.

The Charge sensor informs whether an external power supply is connected to the device either for continuous operation or recharge the battery. It shows the Voltage of the power source, for example, the power supply or a solar panel. The behaviour of each one can be seen below.

Figure 19 – Normal behaviour of a power supply charge

Figure 20 – Normal behaviour of a solar panel charge

At the Figure 20 – Normal behaviour of a solar panel charge is shown:

1. Night period.

2. Day period.

3. Charging the battery. Depending on the amount of sun, the power of the solar panel cannot be enough to charge the battery.

4. Not charging the battery. It can be because the battery is full or because it has not enough sun to charge the battery.

|

|

The Kunak Cloud will inform the user that the device is getting out of battery. Automatically, the platform detects when a device is not powered or the battery is almost discharged and informs the user by generating an alarm (pink status colour). |

The Signal sensor gives measures of the 2G/3G/4G service signal strength in dBm. Signal communications should work within an approximate range from -50 (very good coverage) to -115 dBm (low coverage).

The Temp sensor gives measures of the internal temperature of the device with 0.5ºC resolution. This temperature usually increases when the device is charging the battery.

5.1.2 Environmental Data

Kunak AIR Pro device is a total solution that includes a continuous monitoring system of ambient temperature, relative humidity, dew point and atmospheric pressure.

These sensors are always supplied with the Kunak AIR Pro device and they are needed for advanced algorithms to achieve the highest accuracy, mitigating the effects of temperature, humidity and cross-sensitivities.

The technical data of environmental sensors are explained in the tables below.

|

Parameter |

Type |

Unit |

Measurement Range[6] |

Resolution[7] |

Operating Temperature Range[8] |

Operating RH Range[9] |

|

Temp ext |

Solid state |

ºC |

-40 - 125ºC |

0.01ºC |

-40 - 125ºC |

0 - 100 %RH |

|

Humidity ext |

Solid state |

% |

0 - 100 %RH |

0.04% |

-40 - 150ºC |

0 - 100 %RH |

|

Pressure |

Solid state |

hPa |

300 - 1100 hPa |

0.18 Pa |

-90 to 85ºC |

0 - 100 %RH |

|

Dew Point |

Solid state |

ºC |

-40 - 125ºC |

0.01ºC |

-40 - 125ºC |

0 - 100 %RH |

Table 20 – Technical Characteristics Internal Environmental sensors

|

Parameter |

Typical Accuracy[10] |

Typical 90% confidence interval[11] |

R² Typical precision[12] |

|

Temperature |

± 0.9ºC |

1.5 ºC |

> 0.95 |

|

Relative humidity |

± 3 %RH |

6 %RH |

> 0.95 |

|

Pressure |

± 2 hPa |

3 hpa |

> 0.95 |

Table 21 – Proven performance on field Internal Environmental sensor

5.1.3 GNSS position

The actual position of the Kunak AIR Pro is measured with the build in GNSS sensor that gets the position from GPS, GLONASS receivers.

|

PROPERTY |

DESCRIPTION / VALUE |

|

Type |

GPS, GLONASS |

|

Accuracy |

2.5 meters |

|

Cold Start Time |

35 seconds |

|

Hot Start time |

1 second |

|

Tracking Sensitivity |

-159 dBm |

Table 22 – GPS position characteristics

The GNSS can work in two different ways depending on the application: fixed or mobile. The working mode of the sensor can be changed any time is needed from the Kunak Cloud.

In both cases, each time the Kunak AIR Pro is power on, it gets the GNSS position but if it is configured as a fixed device, it will not take any sample of the position until the next powering off or resetting of the device.

Only if the Kunak AIR Pro is configured to take samples in continuous of the GNSS, the device will take a sample each sampling period and send all the GNSS parameters to the Kunak Cloud. The parameters that will be measured are described in Table 23 – Parameters of GNSS position sensor.

|

PARAMETERS |

UNITS |

DESCRIPTION |

|

GNSS Lat |

deg |

Latitude |

|

GNSS Lon |

deg |

Longitude |

|

GNSS Alt |

m |

Altitude |

|

GNSS Speed |

km/h |

Speed of the device |

|

GNSS Sats |

Sats |

Number of satellites used for the position fix |

|

GNSS HDOP |

|

Horizontal dilution of precision of the position sample |

Table 23 – Parameters of GNSS position sensor in continuous mode

5.2 Smart Cartridge Sensors

5.2.1 Cartridge Overview

We have developed an innovative system of cartridges that integrate the different sensors of the main environmental pollutants. The Kunak AIR Pro can carry up to five cartridges that can be easy & fast replaced or combined with others when necessary (no need to unhook the equipment).

This innovative system makes possible to replace the sensors in a plug & play manner, which means that it is not necessary to dismantle the equipment or send it to the technical service, reducing the time of replacement of the sensors and the time in which the device is not collecting data.

All the cartridges have the same size and fit in any of the five available sockets. Inside the cartridge, we install the sensor into a PCB that stores its all information: type, age and factory calibration. When you plug the new cartridge, the base station just reads the information, configures itself, and starts working.

The cartridges can be connected according to your needs and modify the parameters to be measured over time by simply changing the cartridge. The equipment will auto-configure itself to the connected cartridges and will load its calibrations to work with maximum precision. All the information stored on each cartridge and the calibrations performed will be saved in the cloud to guarantee traceability.

Table 24 – Cartridge sensors slots

|

|

The VOCs sensor cartridge ionises ambient air generating small amounts of O3, so avoid installing it near O3, NO2 or SO2 sensors. For example, place the VOCs sensor in slot 5 and the O3, NO2 and SO2 sensors in slots 1, 2 and 4; avoid placing them in slot 3. |

The equipment includes an automatic cartridge detection system, regardless of the slot to which it is connected. Its advanced LCD display informs about the correct installation and start of the operation of the new installed cartridge.

All cartridges are validated and calibrated in the laboratory against traceable reference standards and include an individualized behaviour algorithm for the sensor (specific curve for each cartridge). Intelligent algorithms that compensate for environmental conditions and the ageing of the sensor element.

|

PROPERTY |

DESCRIPTION / VALUE |

|

Dimensions |

35.5 mm x ⌀57 mm |

|

Weight |

~50 gr |

Table 25 – Cartridge characteristics

Figure 21 – Cartridge overview

The gas sensors are shown in the device and in the Kunak Cloud with their names. In the table below shows how it will be changing the “XX” depending on the name of the gas.

|

Parameter |

Unit measure |

Description |

|

XX GC |

µg/m3, ppb |

Gas Concentration. Shows concentration as it comes from the sensors, including negative values. Only available at devices with operation package. |

|

XX GCc |

µg/m3, ppb |

Gas Concentration Corrected. Shows the corrected concentration, filtering negative values |

|

XX GCc AVG1H |

µg/m3, ppb |

Average 1-hour Gas Concentration Corrected. Only available at devices with analytic package. |

|

XX GCc AVG8H |

µg/m3, ppb |

Average 8-hour Gas Concentration Corrected. Only available at devices with analytic package. |

|

XX GCc AVG24H |

µg/m3, ppb |

Average 24-hour Gas Concentration Corrected. Only available at devices with analytic package. |

Table 26 – Gas sensor names

5.2.2 Multiple Repeated Cartridges

The Kunak AIR Pro is capable of reading multiple cartridges of the same pollutant. In this way, several cartridges can be tested, calibrated, etc. at the same location to compare their performance. This option is available from device firmware version 1.255.3 onwards.

In order to be able to identify each cartridge of the same pollutant in the Kunak Cloud, the tag of each cartridge changes slightly. When there is no repeat pollutant cartridge connected to the device, the tag for each gas is as described in section 5.2.1 Cartridge Overview. But in the case of repeated pollutants, the number of the slot in which it is located is added to the tag from the first detected repeated cartridge.

In the following table you can find an example where in the same device there are 5 cartridges connected, 1 of type “XX” and 4 of type “YY”.

|

Position |

Pollutant Tag |

|

Catridge 1 |

XX GCc |

|

Catridge 2 |

YY GCc |

|

Catridge 3 |

YY GCc_3 |

|

Catridge 4 |

YY GCc_4 |

|

Catridge 5 |

YY GCc_5 |

Table 27 – Example of multiple cartridges of the same pollutant connected to the same device

5.2.3 Stabilization Period

When a Kunak AIR is deployed for the first time in a place, the gas sensors must stabilize. This stabilization variates depending on how much the device was without power, but it is between 1 hour and 5 days.

In order to keep the gas stabilisation period as short as possible when changing the location of the device, it is advisable to leave the equipment on stand-by.

The Kunak AIR gas sensors are very sensitive to abrupt changes in temperature and humidity. For example, a change of more than a 10% RH in less than an hour, may affect some sensors causing invalid measures, above all, the NO2.

5.2.4 Quality Control and Quality Assurance cycle

Table 28 – Quality Control and Quality Assurance cycle

1. Sensors are factory assessed to ensure the good operation of each sensor.

2. Each cartridge with its individual electronics is characterized under specific environmental conditions.

3. (Laboratory) Kunak Calibration against reference standards.

4. Validation of the laboratory calibration against Kunak Gold standards correctly maintained with reference AQMS. Kunak algorithm uses the reference data for validation, not for calibration, to guarantee the best available accuracy.

5. Kunak Cloud allows the devices' remote management and configuration, as well as their data analysis. A calibration tool is available to re-adjust the cartridges remotely. Cartridges can be sent back individually to Kunak for a laboratory re-calibration if required.

6. Once the sensor arrives at its end of life, cartridges are returned to Kunak and the electronics are recycled for new cartridges.

Onboard algorithm

Kunak AIR uses onboard sensors and Kunak embedded algorithm that calculates the concentrations in ppb or μg/m3 locally and in real-time, not using or needing external reference data to calculate gas or particle concentrations.

Kunak algorithm corrects the interferences and artifacts typically found in raw data compensating environmental effects like temperature, humidity and pressure (depending on the cartridge) as well as cross-sensitivities using onboard data.

Benefits

· Calibrate the cartridge for any condition.

· Real-time compensation of temperature effects.

· Traceable QC&QA.

· Not dependant on nearby stations.

5.2.5 Cartridge Specifications

|

Parameter |

Type |

Unit |

Measurement Range[13] |

Resolution[14] |

|

|

K-CO-A-01 |

Carbon Monoxide (CO) |

Electrochemical |

µg/m3, ppb |

0-12,000 ppb |

1 ppb |

|

K-CO-B-01 |

Carbon Monoxide (CO) |

Electrochemical |

mg/m3, ppm |

0-500 ppm |

0.01 ppm |

|

K-CO2-A-01 |

Carbon Dioxide (CO2) |

Non-dispersive Infrared (NDIR) |

mg/m3, ppm |

0-5,000 ppm |

1 ppm |

|

K-NO-A-01 |

Nitric Oxide (NO) |

Electrochemical |

µg/m3, ppb |

0-5,000 ppb |

1 ppb |

|

K-NO2-A-01 |

Nitrogen Dioxide (NO2) |

Electrochemical |

µg/m3, ppb |

0-5,000 ppb |

1 ppb |

|

|

NOx |

Electrochemical |

µg/m3, ppb |

0-10,000 ppb |

1 ppb |

|

K-O3-A-01 |

Ozone (O3) |

Electrochemical |

µg/m3, ppb |

0-2,000 ppb |

1 ppb |

|

K-H2S-A-01 |

Hydrogen Sulfide (H2S) |

Electrochemical |

µg/m3, ppb |

0-2,000 ppb |

1 ppb |

|

K-H2S-B-01 |

Hydrogen Sulfide (H2S) |

Electrochemical |

mg/m3, ppm |

0-20 ppm |

0.01 ppm |

|

K-SO2-A-01 |

Sulfur Dioxide (SO2) |

Electrochemical |

µg/m3, ppb |

0-10,000 ppb |

1 ppb |

|

K-NH3-A-01 |

Ammonia (NH3) |

Electrochemical |

mg/m3, ppm |

0-50 ppm |

0.01 ppm |

|

K-VOCs-A-01 |

Volatile Organic Compounds (VOCs) |

Photoionization |

µg/m3, ppb |

0-3,000 ppb |

1 ppb |

|

K-VOCs-B-01 |

Volatile Organic Compounds (VOCs) |

Photoionization |

mg/m3, ppm |

0-40 ppm |

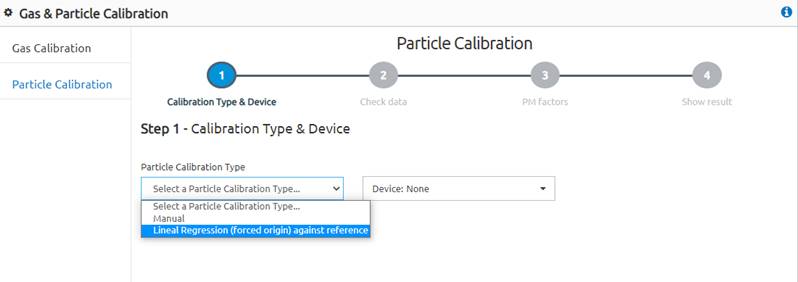

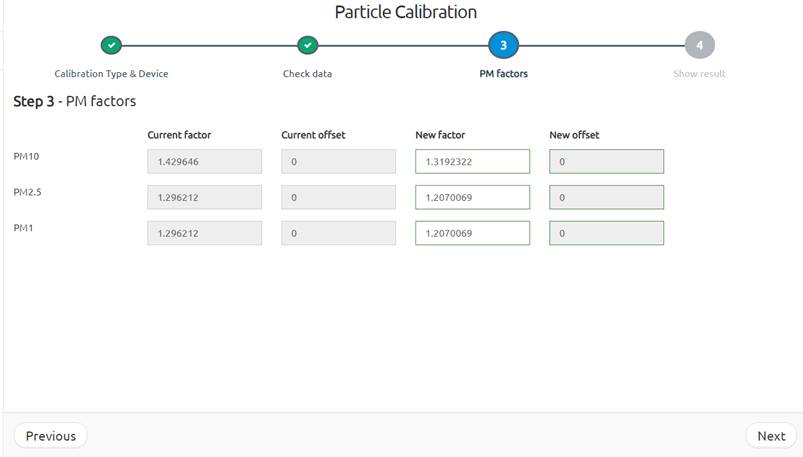

0.01 ppm |